Dispensing Electrically Conductive Materials

When dispensing electrically conductive adhesives, users can be faced with the challenge of dispensing abrasive material with a high degree of accuracy, independent of viscosity.

A new stator has been developed for the microdispenser to facilitate the exact dispensing of abrasive materials.

Microdispensers can provide a dispensing accuracy of 99% (depending on the medium), up to a quantity of 1 µl.

Electrically conductive materials are dispersions that are generally referred to as electrically conductive adhesives, silicones, or inks. The materials are divided into different areas: epoxy resins, polyurethanes, silicones, and acrylates. Epoxy resins, in particular, stand out due to their processing and material properties; they are widely used in industry. The solids they contain correspond to the dispersion phase, and they are electrically conductive. Common particle materials include silver, copper, carbon, nickel, or gold.

Another conductive material is graphene, which is a modification of carbon with a two-dimensional structure. In addition to its high thermal and electrical conductivity, this solid is characterized by its low density and high tensile strength. At present, the first dispensing tests are being carried out to determine when the material will be available for industrial applications; this is not yet foreseeable. According to the first results, though, graphene should be well-suited for applications in the wearable and electronics industries.

Electrically conductive adhesives are used in a variety of industries. The automotive, aerospace, and especially the electronics industries are driving the demand for electrically conductive materials. In addition to the U.S. and Europe, the Asia-Pacific region is predicted to be the core market in the future due to the expected growth of the electronics industry in China and India.

Typical Applications

Typical applications for electrically conductive adhesives include the protection of electronic components against electrostatic discharges (ESDs). They are also used for the direct mounting of unhoused semiconductor chips on printed circuit boards (direct chip attach), where the chip is glued directly onto the substrate. These isotropic materials allow electricity to flow in all directions. They are also used in the assembly of surface-mount devices (SMDs).

Alternatively, anisotropic materials are also available. They allow electricity to flow in only one direction and are used in the manufacture of LCD connections and RFID antennas.

Great potential also lies in the substitution of soldering processes for temperature-sensitive substrates. The curing temperatures of adhesives are significantly lower than those of soldering processes. They are also more flexible than solder metals and can better withstand vibrations. In addition, solvent-free adhesives are more environmentally friendly than solder metals.

Achieving Uniform Solids Content

The particles in electrically conductive materials often have a diameter of 25 µm or more. As a rule, these are coarse disperse systems in which the Shore hardness of the particles exceeds D90. The solids content varies depending on the material manufacturer and application; it is usually between 75-90%, so these materials can be considered highly filled and abrasive.

The difference in density between the dispersion phase and the dispersion material can lead to sedimentation. However, industrial applications require a homogeneous product, since a uniform solids content is required for a valid process. For this reason, suitable dispersion agents are selected that prevent or reduce sedimentation during product storage and processing. This results in high viscosities for electrically conductive materials.

When dispensing these materials, users are faced with the challenge of dispensing abrasive material with a high degree of accuracy, independent of viscosity. This guarantees process reliability and reduces material costs.

Microdispensing

Due to the properties of abrasive fillers, pump types such as peristaltic or rotary lobe pumps are only conditionally suitable for dispensing highly filled materials. Proprietary microdispensers, however, have proven themselves in this field.*

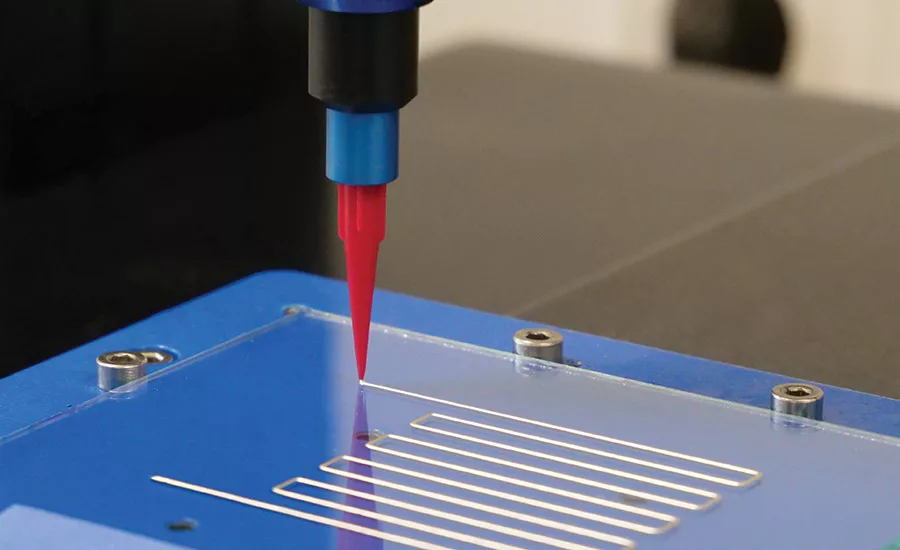

As a progressive cavity pump, these microdispensers are considered rotating positive displacement pumps. The stainless steel rotor moves eccentrically in an elastomer stator. The interaction of rotor and stator creates chambers. The size of the alternating opening chambers is also constant during rotation, so there is no compression of the transferred product. Due to this dispensing geometry, a constant volume is always transferred per revolution, in proportion to the angle of rotation, independent of the viscosity of the dispensing material, and with pulsation-free product flow.

The proprietary microdispensers can provide a dispensing accuracy of 99% (depending on the medium), up to a quantity of 1 µl. Due to the compression-less transferal, highly viscous abrasive and shear-sensitive materials can also be applied.

The endless piston principle’s pump technology provides additional advantages over other dispensing mechanisms. Filling and dispensing valves can be eliminated in over 95% of all applications. A retraction (reversal of the direction of rotation of the dispenser) results in a controlled thread breakage, and dripping is prevented. Thread-pulling gels, resins, or adhesives can therefore be dispensed more precisely.

For the exact dispensing of abrasive materials, a new stator has been developed for the proprietary microdispenser.** The main change is a new stator material that better resists the high mechanical loads of highly filled materials. The user benefits from greater process reliability and longer maintenance cycles.

*preeflow microdispensers from ViscoTec

**eco-PEN330 from ViscoTec

For more information, contact the author at steffen.garbe@viscotec.de or visit www.preeflow.com/en.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!