High-Speed Adhesive Dispensing for High-Voltage Batteries

The high viscosity and high proportion of abrasive fillers in the pastes, adhesives, and sealants used to assemble high-voltage batteries requires specialized dispensing and filling technologies.

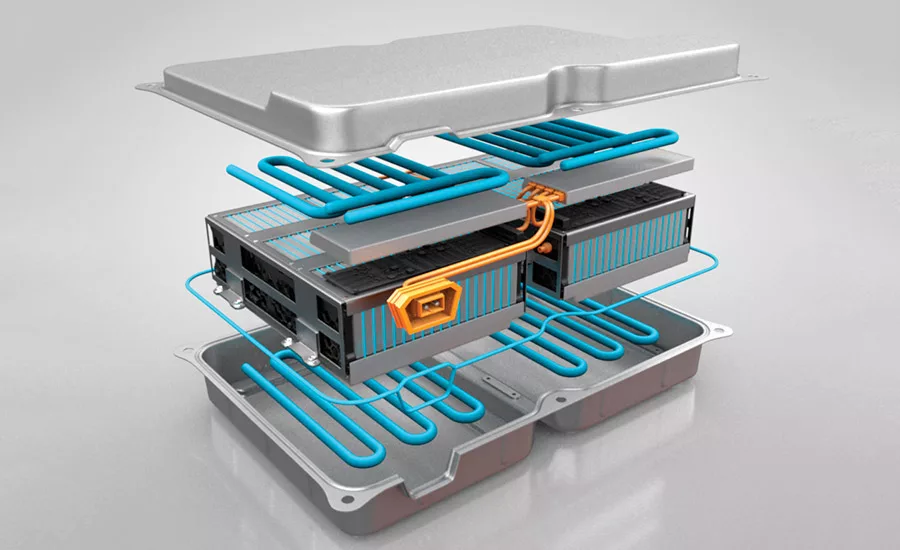

Figure 1. To protect the battery from overheating, several quarts of thermally conductive material ensure a reliable heat transfer between the battery modules and the cooling elements.

(Image courtesy of Scheugenpflug.)

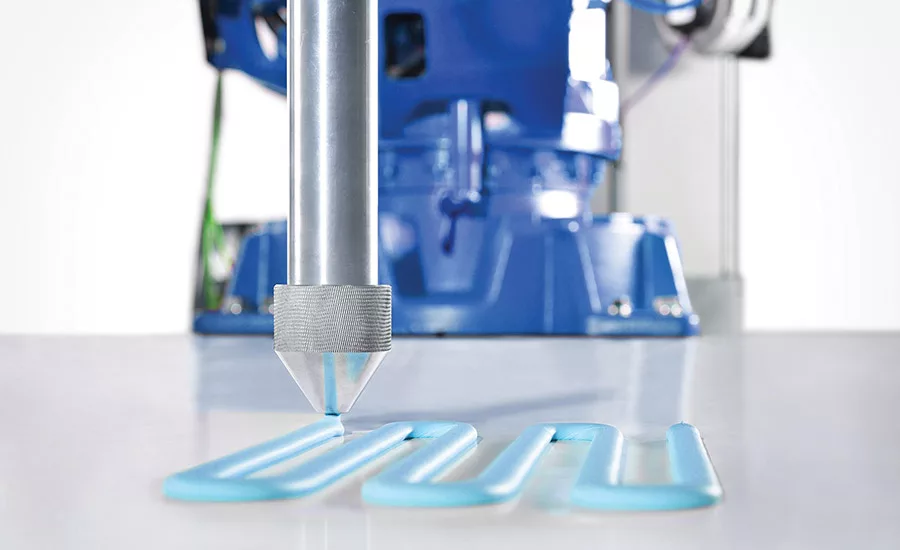

Figure 2. A new system solution for the potting of high-voltage batteries has been developed that consists of dosing and material feeding units.

(Image courtesy of Thomas L. Fischer Photographie)

Thermal influences can significantly affect the service life, capacity, and—above all—operational safety of high-voltage (HV) batteries. In order to prevent damage caused by excessive temperatures, large quantities of thermally conductive pastes, adhesives, and sealants are used. Since the high viscosity and the high proportion of abrasive fillers in these materials usually only allow comparatively low dispensing speeds, it is all the more important to have a high-performance system technology that is precisely matched to the application.

Electric mobility is picking up speed: Vehicles with alternative drive systems are regarded as a key component in the fight against noise pollution and constantly rising emissions in densely populated areas. With a view to current environmental and climate protection targets, various European countries are already planning to abandon the combustion engine. China, which is currently the world’s largest market for electric vehicles, reported over 1 million electric cars sold last year. According to management consultancy McKinsey, the local market grew by 85% in 2018.

In addition to the electric motor and power electronics, a core element of these vehicles is the HV battery. According to the current status, lithium-ion technology has emerged as the dominant technology here, as it currently exhibits the best performance in comparison to other options. The HV battery consists of hundreds to thousands of individual cells of various shapes and performance classes, which are assembled into modules and finally into a complete battery.

The design of the individual cells varies depending on the manufacturer or vehicle manufacturer. Cylindrical and prismatic shapes are used, as well as pouch cells that are also referred to as “coffee bag” cells due to their external resemblance to vacuum-packaged coffee powder. The decision for a certain cell format is linked to several central factors for the vehicle manufacturer, such as manufacturing costs, energy density, weight, and scalability. Also essential are the properties of the cells in terms of heat generation and the associated cooling requirements.

Heat-Conducting Materials

For the normal operation of an electric vehicle, outside temperatures of 50-77°F and operating temperatures of approximately 68-104°F are ideal. Applying higher thermal loads not only causes faster degradation of the materials used in the battery cells—in the worst case, failures or severe to irreparable damage to the HV battery and vehicle may occur.

To prevent this, every electric vehicle has a cooling system built into the battery housing. The cooling system is controlled by the battery management system (BMS), which, in addition to thermal management, is also responsible for monitoring the charging and discharging process. To ensure optimum heat dissipation, the battery modules and cooling elements are thermally coupled with heat-conducting pastes, adhesives, or sealants (see Figure 1). Several quarts of these highly viscous media enriched with heat-conducting fillers are used per vehicle. Depending on the filler density, this can correspond to a material weight of up to 44 lbs (20 kg).

These materials provide reliable heat transfer and help prevent potential defects due to overheating. However, due to their high viscosity and the high proportion of abrasive fillers, the application of heat-conducting materials poses a challenge. Since these media often only allow comparatively low dispensing speeds, this process step often proves to be a bottleneck, especially in fully automated production processes with fast cycle times such as those in the automotive industry. If no special attention is paid here to fine-tuning the dispensing and material feeding technology, users also risk high maintenance and repair costs.

Dispensing Solutions

A system solution that addresses these issues has been developed, comprising a dispenser and a compatible material feeding system.* The system offers consistent and accurate dispensing speeds of up to 80 ml/s, even with highly abrasive potting materials.

The high-performance volumetric dispenser enables the fast and precise application of thermally conductive media with a viscosity of up to 1,000,000 mPa·s. The maximum volume per dose is 370 ml. Two electric motors in the dispenser ensure the required performance. An additional metal sleeve reinforces the mixing tube and ensures the necessary stability during material application. To ensure a sufficiently large operating range for the application, the unit is usually mounted on an industrial robot.

The dispensing system is based on the system technology of a proven volumetric piston dispenser that was up-scaled and optimized especially for the discharge of very large material volumes in a short time.** With this dispensing system, users also benefit from the advantages of volumetric dispensing. The mechanical design principle enables not only long service lives, but also simple and fast maintenance and therefore reduced maintenance costs. In addition, precisely dimensioned dispensing cylinders ensure the output of precise, reproducible material volumes.

The fast and process-reliable feeding of material to the dispensing system is carried out by a drum follower plate system, which has been specially designed for 55-gal drums.† The delivery volume of the integrated double-piston pump is 480 cm3/stroke; the maximum delivery pressure is 65 bar.

In addition to a continuous pumping process, the pump also offers long service lives, as the piston only comes into contact with the abrasive dispensing material on one side. A rinsing fluid on the back prevents the contained fillers from adhering to the seal and pump components. As an option, two feeding systems can also be connected in parallel to the dispenser, allowing for redundant system operation without downtimes.

*Dos HP from Scheugenpflug **Dos P from Scheugenpflug †PailFeed200 Abrasive from Scheugenpflug

Reducing Bottlenecks

The application of thermally conductive media is often a bottleneck in production, especially in industries with highly automated manufacturing processes. However, modern manufacturing technology can also effectively alleviate this bottleneck. Fine-tuned integrated solutions are a more economical solution than individual systems, because material preparation, dispensing, mixing, and control technology can be optimally tailored to each other with regard to the materials used.

For more information, contact the author at (770) 218-0835 or gabriele.mcfarland@scheugenpflug-usa.com, or visit www.scheugenpflug-usa.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!