Product Profile

High-Performance Adhesive Dispensing for Electronics Applications

New dispensing technologies offer the electronics industry maximum productivity, flexibility, and functionality.

The electronics market is booming, and its trends toward component miniaturization, increasingly short cycles, and highest dispensing quality require constant innovation. Dispensing systems are key technologies in an environment of increasing automation and demand for high product output.

Scheugenpflug reports that it has introduced two dispensing solutions to support electronics production in the automotive, industrial, medical, and consumer markets for dispensing small quantities and up to 10 times higher dispensing speeds. These new products offer maximum productivity, flexibility, and functionality to cope with increasing material viscosities, decreasing cycle times, and reduced dispensing quantities.

High Performance

Material usually must be dispensed as quickly as possible when using high-viscosity materials, such as thermal interface materials (TIMs), whether for control units or battery systems. A high-performance dispenser like Scheugenpflug’s DosP DP2001 is reportedly able to dispense up to 10 times faster than comparable solutions. It dispenses one-component materials from 0.06-20 ml and two-component materials from 0.1-40 ml. The high dispensing speed for highly automated production lines enables a new valve system with extremely short switching times. It works without a diaphragm and is pressure stable.

The new technology is particularly advantageous in combination with the piston dispensing principle, meaning not only the smallest points and lines can be dispensed. The system also offers a high degree of flexibility in terms of dispensing rates and volumes. Powerful servo drives ensure the high dispensing speeds. In addition, new process possibilities arise, such as adaptation of the mixing ratios to product-specific properties. This ensures greater flexibility and thus an extended range of applications.

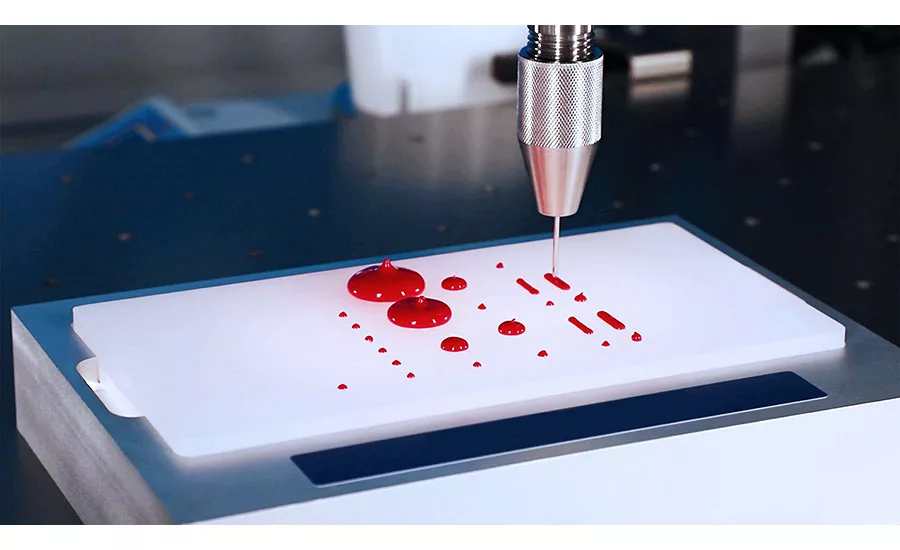

The high-performance DosP DP2001 is up to 10 times faster than existing dispensing units.

Maximum Flexibility

The trend toward the miniaturization of electronic components is leading to increasingly small dispensing quantities and potting volumes. The recently introduced DosPL DPL2001 low-volume dispenser dispenses dots smaller than pin heads quickly, reliably, and with maximum repeat precision. The dispensing quantity includes one-component materials from 0.003-2 ml and two-component materials from 0.006-4 ml. This high dispensing accuracy with fast cycle times is made possible by a new displacement-free valve system, which is also suitable for the use of abrasive materials due to its robustness.

Whether for bonding, sealing, filling, or heat dissipation, their simple, robust design makes piston dispensers appropriate to use for many different tasks and a wide range of materials. In addition to very liquid adhesives, sealants, and potting materials, piston dispensers are also suitable for highly viscous and/or filled and highly abrasive materials. The DosPL DPL2001 can be used to dispense extremely small volumes down to a few μl. At the same time, the maximum cylinder filling of up to 4 ml with two-component materials ensures maximum flexibility.

The DosPL DPL2001 is based on advanced low-volume dispensing technology, which makes it the right choice for a wide range of smaller component designs and applications. The volumetric piston dispensing principle, in combination with the advanced sensor technology, ensures highest precision and process reliability during dispensing. The smallest dots and thinnest lines as well as accurate micro-fillings can thus be reliably performed. High dispensing speeds and extended service lives contribute to maximum efficiency in fully automated production environments.

Additional Benefits

According to Scheugenpflug, both dispensing solutions feature reliable process monitoring and access to relevant process parameters. The new sensor technology and software continuously monitors the dispensing pressure by component. Improved start/stop behavior as well as more precise contours are additional advantages, especially in the smallest quantity range, and are made possible by the new parameter selection of the material-specific dispensing pressure in the dispensing program.

Both dispensing units can be used in the multi-function DispensingCell DC803 for atmospheric applications. Alternatively, they can also be used as an integration solution in conjunction with the process module.

For additional information, visit www.scheugenpflug-dispensing.com.

Note: Images courtesy of Scheugenpflug GmbH.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!