Strategic Solutions

Collaboration and Innovation for Sustainable Packaging

Ink, adhesive, paperboard, film, and other material suppliers need to understand relevant certifications and processes in order to adhere to recycling or composting standards.

Illustration of resealable adhesive.

(Photo courtesy of Bostik.)

Consumer sentiment continues to drive sustainability throughout the economy and society. Consumers often view packaging as wasteful, and they demand more sustainable options as a result. Many terms, such as reuse, recycle, compost, and reduction, resonate positively with consumers. Unfortunately, a poor understanding of the definitions may prevent proper disposal and realization of sustainable benefits.

In response to consumer demands, many fast-moving consumer goods (FMCG) brands, including Unilever, PepsiCo, and the Coca-Cola Co., as well as major retailers such as Walmart and Target have established sustainability pledges. Brand owners and retailers are no longer limiting themselves to carbon dioxide (CO2) emissions and post-industrial promises; their priorities also include end-of-life (EOL) packaging.

Recyclability has become a key requirement, as many brand owners have promised 100% recyclable or compostable packaging by 2025-2030. This is a leading innovation driver downstream among brand owners’ packaging, adhesives, and raw materials suppliers.

Collaboration is a Must for Sustainability

For packaging to avoid the landfill or incineration process, all components should adhere to recycling or composting standards. This requires ink, adhesive, paperboard, film, and other material suppliers to understand relevant certifications and recycle processes. This is no easy task and requires substantial industry collaboration.

In 2019, Bostik released the first BPI-certified compostable hot-melt adhesive at PACK EXPO. The introduction of this grade required us to dig into the certification process from BPI and work with many companies in the industry to realize the innovation. While the main challenge was to formulate a product that decomposed under the right conditions, we also worked with our raw material suppliers to ensure our adhesives would not impart harmful chemicals on the compost stream.

While a safe adhesive was a must, we still needed our raw materials to offer good processing and adhesion properties. Further, our customers required excellent performance and competitive costs. Finding the right balance between certification, processing, performance, and cost was a major hurdle. Without open collaboration, we may very well still be in the lab phase.

While our compostable development is just one example, developing robust recyclable packaging requires similar efforts. There are clear differences in recycling paper-based products and plastics; however, these differences can change further based on region or country. Even the types of plastic that are accepted differ based on location. Prioritizing information sharing and collaboration between recyclers, trade organizations, material producers, and brand owners is the key to achieving sustainability goals.

Collaborative Innovation Pays Off in Flexible Packaging

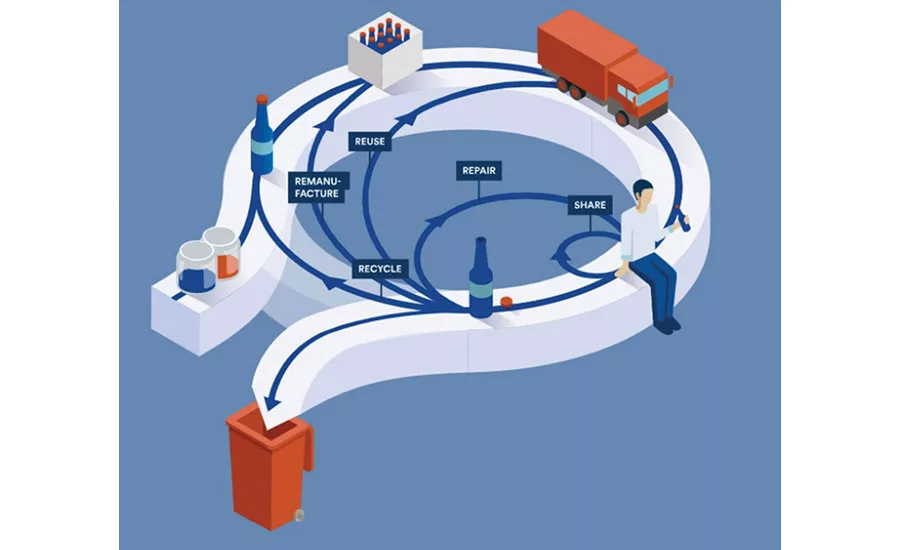

The European Commission’s concept of a circular economy is gaining considerable traction in North America as it begins to influence flexible packaging design and material selection. A continuous material lifecycle (a complete loop) depends on collaboration throughout the flexible packaging supply chain. The collaboration must focus on how packaging design impacts material recovery (recycle), reuse, and reduction, or the selection of renewable sources.

One example of material reduction by design is plastic thermoformed trays typically molded from polyethylene terephthalate (PET) or amorphous polyethylene terephthalate (APET) with mechanical easy-open-and-close rigid lids. By replacing the mechanical lidding with flexible films, a substantial weight reduction of about 30% can be realized.

Another benefit to flexible film lidding is the ease of removal prior to recycling. Typical rigid lids include labels, which often contaminate the recycling, resulting in land-filled trays. Instead, the lid can include all pertinent product information and be properly disposed of while the bulk of the package (tray) is recycled.

Historically, a drawback to the use of filmic lids is the need for multi-layer films and coatings, particularly a polyethylene (PE) sealant to a primed surface on the PET tray. The primer is required for PE sealants to create a sufficient bond to PET trays. Instead, Bostik adapted our co-polyester chemistry for heat seal coatings. The chemical similarities of co-PET and PET eliminate the need of primers and reduce contamination of PET trays for recycling. Further, the continued recycling of PET trays results in a more challenging surface to bond; thus, a higher adhesion chemistry like co-PET offers benefits over PE sealants.

While the weight reduction offered by flexible films is substantial, these films can only truly compete with mechanical closures once a resealable adhesive is incorporated. Today, there are two widely used adhesive systems in the market for reseal. The first are water-based adhesives, which are typically gravure applied between two films (one of which must be heat sealed to the tray). The film is later laser scored to allow for a resealable layer.

Extrudable hot melts can also offer reseal properties when used in a coextrusion blown film process. The reseal hot melt is trapped between a heat seal layer (bonded to the tray) and one or more layers above it. The reseal is exposed during the first opening, and it can be reclosed under pressure for future uses.

All re-closure systems offer packaging benefits, including the elimination of compensatory packaging like a plastic bag or over-wrap. The convenience of the re-closure systems encourages consumers to save food for the future, likely reducing food waste. Reseal adhesives differentiate from mechanical re-closure, because they also reduce packaging weight.

Continued Cooperation

The recent strides made in sustainable packaging are the result of tireless collaboration between suppliers, converters, brand owners, recyclers, and trade organizations. The continued adoption of these solutions is dependent on our continued cooperation and openness.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!