Buyers Guide

Are you sure you want to leave before submitting your RFP?

Search our Buyer’s Guide to find suppliers, manufacturers, and distributors of adhesive and sealant equipment for formulation and production.

ChemQuest Group

Company Profile

ChemQuest Group, ChemQuest Technology Institute/ChemQuest Powder Coating Research

9435 Waterstone Blvd., Ste. 270

Cincinnati,

OH

45249

United States

Phone: (513) 469-7555

(434) 570-1400

Fax: (513) 469-7779

The ChemQuest Group, a global consulting firm with focus and expertise in adhesives and sealants, is widely recognized among raw material suppliers, formulators, and financial investors for services including business strategy, market research, and third-party product formulation, with application and lab services through ChemQuest Technology Institute and ChemQuest Powder Coating Research.

Product Categories

Articles

War in Ukraine: Ramifications for Industries and Supply Chains

Brad Boelkins of ChemQuest shares his thoughts regarding the current situation in Ukraine, potential supply chain impacts, and more.

March 8, 2022

Kramer Joins ChemQuest as Director

With expertise in manufacturing operations, process optimization, and business development, Robert G. Kramer will aid in the expansion of ChemQuest’s Manufacturing Excellence pillar.

February 9, 2022

Boelkins Joins ChemQuest as Vice President

Boelkins joins ChemQuest after a 33-year career with tesa tape, inc.

January 18, 2022

Strategic Solutions

PSA Wound Dressing Adhesion and Skin Type: A Delicate Balance

Consideration must be given to various skin types to ensure dressings can be securely attached and easily removed without skin damage.

December 15, 2021

Duan Named Vice President at ChemQuest

Robert G. Duan has held senior R&D leadership positions at Dow Chemical, Valspar, and Sherwin Williams.

December 15, 2021

Strategic Solutions

Sustainable Adhesives in Construction and Packaging

Though sustainability can be difficult to define, many types of adhesives contribute to more sustainable construction and packaging products.

November 8, 2021

Strategic Solutions

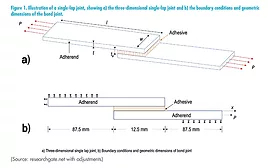

Assembly with Adhesives

Three key steps must be undertaken when considering the use of adhesives in assembly operations.

October 11, 2021

Strategic Solutions

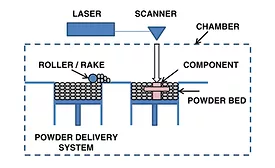

Weighing the Cost Benefit of Complex Design in 3D-Printed OEM Parts

Adhesive bonding opportunities are exponentially increasing with the design complexities of polymer and metal additive manufacturing.

September 10, 2021

ChemQuest Acquires Powder Coating Research Group

The acquisition brings powder coating formulation expertise and a third laboratory to ChemQuest, in addition to liquid formulations and application and molecular architecture.

August 13, 2021

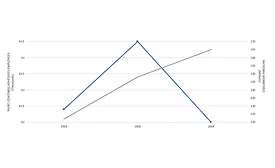

2021 Raw Materials and Chemicals Overview

The outlook for industrial demand is expected to improve, notwithstanding inflated raw material costs.

July 29, 2021

ChemQuest Announces Leadership Appointments

Appointments include a chief commercial officer, vice president, and communications director.

July 15, 2021

Equi Joins ChemQuest as Director

Equi's work experience has spanned the Americas, Eastern Asia, and Western Europe and has culminated in many successful strategic growth opportunities.

April 22, 2021

Gibson Joins ChemQuest as Director

Rich Gibson has extensive experience in business strategy development and the specialty chemicals market.

March 3, 2021

Braggio Joins ChemQuest Europe as Vice President

With over 35 years of experience, Braggio has worked as an executive for both Sherwin-Williams and PPG Industries.

January 19, 2021

2020 Raw Materials and Chemicals Overview

What repercussions has COVID-19 had on price fluctuations and availability for key raw materials used in the adhesives and sealants industry?

November 4, 2020

Strategic Solutions

What Tests Should I Run on My Structural Adhesive Systems?

Each adhesive testing protocol should add tangible value to your structural design.

October 14, 2020

Davenport Named Newest ChemQuest Director

A specialty chemicals industry veteran, Karl Davenport brings over 35 years of global experience to ChemQuest.

October 9, 2020

Strategic Solutions

Collaboration and Innovation for Sustainable Packaging

Ink, adhesive, paperboard, film, and other material suppliers need to understand relevant certifications and processes in order to adhere to recycling or composting standards.

September 4, 2020

Blackburn Joins ChemQuest as Director of Intellectual Property

Sapna Blackburn has more than 20 years’ worth of R&D and subject matter expertise in materials development and intellectual property (IP) generation and protection.

August 24, 2020

Strategic Solutions

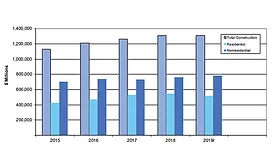

Market Dynamics for North American Sealants

Through 2019, the building and construction market was a sealants volume leader, followed by assembly operations and transportation.

August 17, 2020

Strategic Solutions

Switching Production to Satisfy Shifts in Demand

Production cycle planning and excess capacity can yield unexpected advantages.

July 7, 2020

Strategic Solutions

Formulation and Availability of Building and Construction Adhesives, Sealants, and Other Materials

Engineers, architects, specifiers, facility managers, and homeowners must spend time analyzing what performance levels can be obtained by the adhesive and sealant products that are available to them for the environments in which they are being used.

May 15, 2020

Strategic Solutions

Driving Innovation by Collaborating with Others: Know Your Areas of Focus

Scouting for collaboration opportunities outside your company is a process that begins with defining and prioritizing the market's needs in a way that anyone unfamiliar with your business can understand.

April 20, 2020

Strategic Solutions

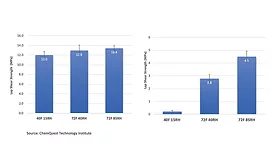

Third-Party Validation of Adhesive Performance

This second installment of a two-part series higlights the value proposition of independent material testing and validation to high-value end-use markets.

March 27, 2020

Strategic Solutions

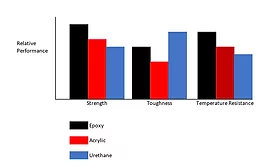

Evolving Hybrid Adhesives

This first installment of a two-part series highlights the value proposition of today's adhesive chemistries and curing methods to high-value end-use markets.

February 13, 2020

2020 Raw Materials and Chemicals Roundtable

In response to continued uncertainties, raw materials and chemicals suppliers are undertaking a number of strategic initiatives.

February 3, 2020

Strategic Solutions

Will Your Next Car be Assembled Like a Smartphone?

Electrically conductive adhesive use is rising as fine spacing, environmental restrictions, and new materials impact or replace vehicle assembly methods.

June 18, 2019

Keep the info flowing with our newsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

-780x439.webp?height=168&t=1762987360&width=275)