Strategic Solutions

Sustainable Adhesives in Construction and Packaging

Though sustainability can be difficult to define, many types of adhesives contribute to more sustainable construction and packaging products.

The definition of “sustainability” is in flux. As it pertains to construction, sustainability is constantly evolving to encompass varying approaches and priorities. In the U.S., sustainable construction is the method of creating buildings and using processes that are environmentally reliable and resource efficient throughout the building’s life cycle, including design, construction, operation, and renovation. Western Europe defines sustainable construction as a way to build that aims to reduce health and environmental impacts affected by the construction process or by buildings.

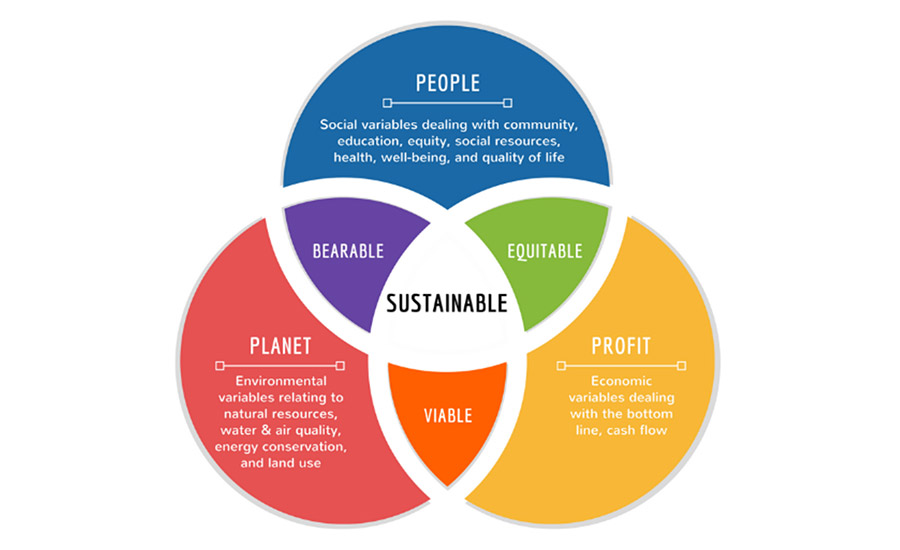

Everyone agrees that sustainability is the direction to move toward, but not everyone agrees on its definition (see Figure 1). Currently, sustainability remains a moving target.

Construction

Sustainable adhesives are of concern to businesses and the public all over the world. With each passing month, we are introduced to new, groundbreaking ways of being “greener.” Companies are recognizing the change in consumer needs and behavior, as well as their own accountability when it comes to the environment. Although the tallest wooden skyscraper at 85 m in the Netherlands is impressive, it was primarily constructed using traditional fasteners and some adhesives.

To be considered sustainable, adhesives can be classified a number of ways. Biodegradable adhesives are intended to be broken down by bacteria and other living organisms. During the degradation process, these adhesives lead to the production of carbon dioxide, water, and other natural gases depending on the environmental conditions. Synthesized using natural raw materials and based on renewable materials, they are best for packaging applications, envelopes, hygiene products, and medical devices.

Compostable adhesives are broken down in a compost pile environment. Designed to work in our existing waste remediation systems, these adhesives leave no harmful residue or waste behind once fully composted. The resulting compost can then be used to improve and fertilize the soil.

Adhesives are considered renewable materials when they have no petroleum derivatives in their formulations. In addition to a decreased carbon footprint, they further enhance overall sustainability content for many applications.

An adhesive is repulpable when it dissolves completely in water during the paper repulping process. Since they are fully soluble in water, these materials are ideal for cardboard boxes, envelopes, and other paper product applications. The adhesives’ ability to dissolve eliminates the film or residue that is normally left behind.

Adhesives are designated recyclable when they are fully compatible with the substrates they are bonded to and can be fully melted down without yielding any adhesive waste or residue when the end-use product has reached its end of life. These adhesives are used for automotive applications, as well as for glass, aluminum, and steel bonding needs.

Bio-based raw materials available for the production of renewable adhesives and sealants include:

- Succinic and other diacids

- Natural oil polyols

- CO2-based polyols

- Bio-isobutanol and 1,4-butanediol

- Bio-based isocyanate alternatives

- Furan dicarboxylic acid (FDCA) and esters

- Bio-based epichlorohydrin

Several companies are also producing bio-based solvents (e.g., acetone, ethyl acetate) that have been used in adhesive and sealants.

Figure 1. Factors to consider when defining sustainability. (Image courtesy of Research Gate.)

Packaging

Packaging is a key use for adhesives, so it is certainly an area for further sustainability-related consideration. Food and beverage packaging materials make up nearly half of municipal solid waste.1 When it comes to the damage that human activity is causing the planet, packaging waste is a big part of the problem.

New terms such as “biodegradable,” “compostable,” and “bio-based” have recently surfaced for packaging materials. Similar to adhesives, the understanding behind these terms is rather hazy. Today, people are choosing to buy biodegradable packaged products over other forms of packaging because they have heard it’s better for the planet. They often only listen to the top half of the story and don’t consider life cycle analysis or anything deeper than what the plastic is made from.

Although plastic packaging is maligned, it can be sustainable if used and managed in the right way. The process of converting used materials into something new keeps products out of landfill for longer, and it is often forgotten that plastic production uses about half as much energy as alternative materials. Studies have shown that, overall, consumption of packaging mass, energy, and greenhouse gas emissions would increase if there were no plastic packaging available and only other materials were used.

The market for vegetable oil-based polyester polyols, which are also used for polyurethane (PU) manufacture, continues to grow, with improvements achieved in performance. Interest is growing in alternative bio-based diacids and diols. In addition to succinic acid, examples include: 1,3-propanediol; octadecanedioic acid; and 2,5-furandicarboxylic acid (FDCA).

Bio-based adhesives and raw materials will be successful if they are needed to meet regulatory requirements, if they offer novel or multifunctional properties, or if they offer competitive or better performance than existing products on the market. It is anticipated that this market segment will continue to grow throughout this century.

For more information, call (513) 469-7555, email info@chemquest.com, or visit www.chemquest.com.

Note: Opening image courtesy of metamorworks via iStock/Getty Images Plus.

Reference

1. “The Environmental Impact of Food Packaging,” FoodPrint, https://foodprint.org/issues/the-environmental-impact-of-food-packaging/.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!