Strategic Solutions

Weighing the Cost Benefit of Complex Design in 3D-Printed OEM Parts

Adhesive bonding opportunities are exponentially increasing with the design complexities of polymer and metal additive manufacturing.

Additive manufacturing (AM), also known as 3D printing, has seen increased adoption across industries and regions for producing a variety of end-use parts. In 2020, traditional personal protective equipment supply chains, operating under reduced capacity or entirely shut down, heavily relied on AM. Prior to COVID-19, just-in-time manufacturing was a key driver for AM to gain a foothold in specific industries when traditional manufacturing methods could not meet the timeframe for low-quantity orders.

Even with the impact of 2020, the global market value of 3D-printed parts is projected to increase at around a 15% CAGR from 2020-2030, rising from $12 billion last year to $51 billion by the start of the next decade. The medical and dental industries are anticipated to represent the largest share of end-use parts at $4.5 billion by 2030, followed by aerospace at $3.9 billion.1

Less visible but equally valued are the incremental improvements in product performance delivered by AM. From the OEM’s perspective, however, when increased performance relies on increased design complexity, this can create manufacturing challenges with inspection, post processing, and downstream operations. Anticipating and mitigating the challenging aspects of intricately designed products is critical for quality assurance and profitability.

Given the emerging just-in-time dynamics and market pressures for ever-faster solutions, adhesives may be a good option for assembling AM components in final products. In order to find suitable bonding solutions, collaboration among adhesive R&D teams, AM experts, experienced OEM product engineers, and designers is essential to profitability for the adhesives and sealants value chain in transportation and assembly operations markets.

Understanding Additive Manufacturing

As the name implies, additive manufacturing builds parts by adding material one layer at a time to create a net shape. This can be done in several ways using different energy sources and material feedstock forms.

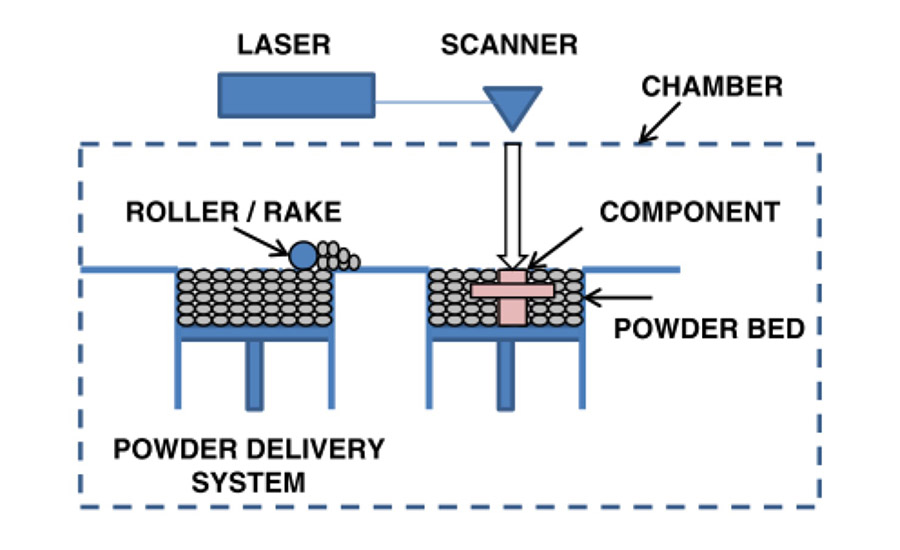

One common process uses a powder feedstock that is melted by a laser. As the laser moves, it locally melts a specific section of the part. This process is called laser powder bed fusion (L-PBF) for metals (see Figure 1) and selective laser sintering (SLS) for polymers.

Figure 1. Illustration of the powder bed fusion additive manufacturing process. (Source: http://canadamakes.ca/what-is-powder-bed-fusion/.)

Figure 1. Illustration of the powder bed fusion additive manufacturing process. (Source: http://canadamakes.ca/what-is-powder-bed-fusion/.)Similarly, an electron beam energy source (E-PBF) can also be used with metal powders. Other common methods include: fused filament fabrication (FFF), which extrudes a thermoplastic filament feedstock through a heated nozzle; and stereolithography (SLA), which pairs a laser or projected light source with a polymer resin bath that hardens after exposure.

While a common mantra for AM has been “design complexity is free,” complexity is rarely (if ever) free in reality—it adds front-end labor with designers and analysts, as well as back-end labor with intricate support removal and inspection. While design complexity may add cost, the payoff is in overall design freedom, which opens the door to significantly improved functionality.

Advancements in design software and printable materials are leading to a rapid expansion in industrial use cases and capabilities. One challenge to consider is how these complex parts can be easily and efficiently assembled with other AM or traditional parts.

Increased Design Complexity Requires Compatible Adhesives

Given the challenges of rapid manufacturing and assembly, the role of adhesives should be evaluated. Consider these common questions:

- How can you accommodate for an inconsistent interface?

- How does variable surface roughness affect the bond strength?

- What is needed to prepare the bond area?

In order to evaluate an adhesive, the intended bonding surface needs to be understood. The surface condition of a part right out of the printer is called “as-built” or “as-printed.” Unlike machined, molded, or extruded products, these as-printed surfaces are often rougher due to the presence of layer lines and the morphology of the feedstock itself.

As-printed surfaces vary based on material, technology, geometry, and print angle from the build platform. This rougher surface can be a benefit if it reduces the amount of work needed for initial surface preparation prior to bonding. However, other areas of the part may still need surface finishing operations to meet final requirements. Knowing what finishing steps are needed, which can be reduced, and where to apply them is important to realizing a cost-effective part.

As greater adoption of AM leads to a wider variety of products (some within complex assemblies), new adhesive systems, forms, and methods will be required. Each form of adhesive—from sprays to gels to foams—will have its own place in manufacturing and assembly operations. The key to an effective workflow is to identify the compatible adhesive and develop a repeatable technique for the application.

Multi-Step Development Process

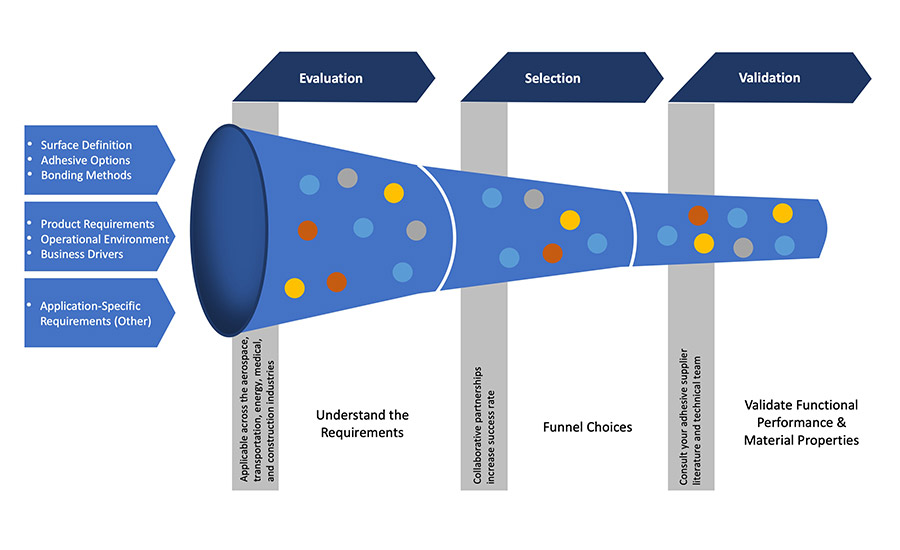

Developing a new concept from prototype to production is a multi-step process (see Figure 2). From the start, it is important to evaluate and identify the basic functional requirements. What are the performance expectations? What is the operating environment? What are the loading conditions? It is necessary to determine answers to these basic questions at the beginning, as scope creep can easily occur when additional requirements are imposed later in a project.

Figure 2. Qualification process for a bonded joint. (Source: “2020-2023 North American Market Report for Adhesives and Sealants, with a Global Overview,” www.ascouncil.org.)

Figure 2. Qualification process for a bonded joint. (Source: “2020-2023 North American Market Report for Adhesives and Sealants, with a Global Overview,” www.ascouncil.org.)

After functional requirements have been determined, the materials are selected and workflow defined. Next, the test plan is written and cross-checked against the application and industry-specific requirements. Representative validation testing is the last step. It is meant to compare the measured test results against the predicted performance or a legacy product’s performance.

Understanding where to begin a new project can seem overwhelming. Working with AM experts and adhesive R&D teams to evaluate project feasibility and scope helps avoid internal bias and bridge knowledge gaps. As global production comes back online, additive manufacturing will serve a critical role to improve the reliability and capacity of domestic and international supply chains.

For more information, email info@hummingbirdadditive.com or visit www.hummingbirdadditive.com or https://chemquest.com.

Reference

1. “Lux Research Forecasts the 3D Printing Market will Reach $51 Billion in 2030,” April 8, 2021, www.luxresearchinc.com/press-releases/lux-research-forecasts-the-3d-printing-market-will-reach-51-billion-in-2030.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!