Case Study

Ferrari Achieves an Invisible Bond with a New Epoxy Adhesive

A new two-part epoxy adhesive has enabled Italian sports car manufacturer Ferrari to solve an existing adhesive issue for a new automobile development.

The requirements for the bonding of carbon parts are getting more and more demanding. Kisling, a Switzerland-based manufacturer of adhesives, has developed a new 2K-epoxy to improve bonding performance for a variety of applications in the automotive industry. In fact, the ergo® 7440 epoxy adhesive enabled Italian sports car manufacturer Ferrari to solve an existing adhesive issue for a new automobile development.

Almost Invisible Composite Bonding

The issue to be solved was to remove the bondline read through (BLRT). Due to the low shrinkage capabilities of the ergo 7440, this primary requirement has been met to full satisfaction. The additional benefit of having an almost invisible glue line was accomplished due to the black color of the epoxy adhesive.

High Temperature Resistance

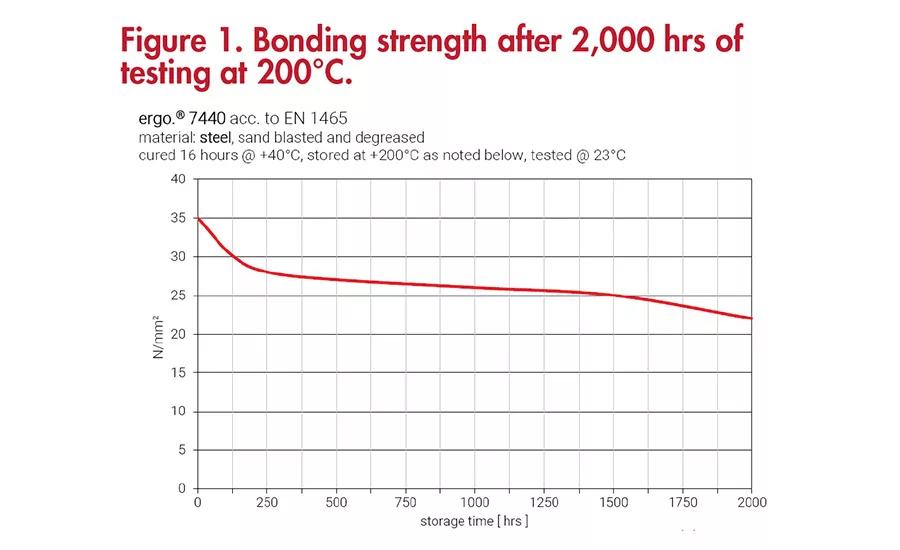

Another requirement was the permanent temperature resistance of 180°C. This performance criteria had to be proven through a 2,000-hr test. As can be seen in Figure 1, the Kisling ergo 7440 adhesive provides high bonding strength after 2,000 hrs of testing at 200°C.

Defined Bonding Gap

A defined bonding gap is ensured by additives incorporated in the epoxy adhesive. This feature avoids contact corrosion in metal-carbon connections.

Long Open Time

A processing time of 40 min ensures that there is enough time for the bonding process, even with high ambient temperatures during summertime. In addition, ergo 7440 delivers a fast buildup of handling strength after 3.5 hrs. This fast handling strength allows quick turnaround times in production.

For more information, visit www.kisling.com. Ferrari is online at www.ferrari.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!