Product Profile

UV-Activated Silicone Adhesives for Autonomous Automotive Sensors

Newly developed UV-activated, dual-cure silicones can protect sensors in autonomous vehicles from the heat, cold, moisture, and stress that result from the rigors of the automotive environment.

Light detection and ranging (LiDAR) is a surveying technology that measures distance by illuminating a target with a pulse of light. In use for over 60 years in military, aerospace, robotics, and meteorological applications, LiDAR is currently experiencing a boom of interest due to the expectation that it will be one of the main types of sensors to enable autonomous, or “self-driving,” cars.

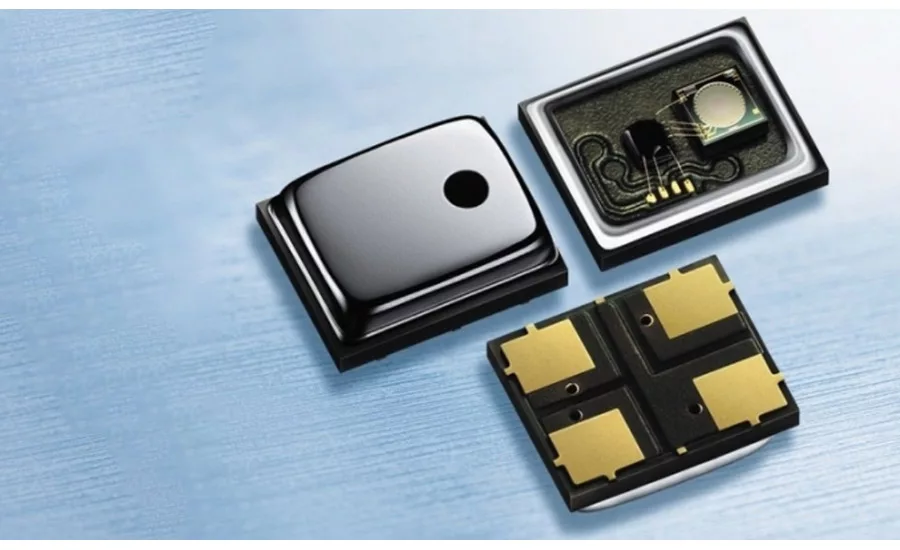

Within this realm, advanced driver-assistance systems (ADAS) utilize silicone around their automotive packages (e.g., camera, radar, etc.) in order to seal them from the external environment. Additional uses in these advanced device package areas also include potting/encapsulating for microelectromechanical systems (MEMS) and optical bonding.

Automobile manufacturers have identified approximately 200 sensor areas around the vehicle that will be instrumental in achieving commercialization and meeting safety goals. The main commonality is the need to protectively seal these key sensor platform areas from the heat, cold, moisture, and stress that result from the rigors of the automotive environment.

UV-Activated, Dual-Cure Silicone Solutions

In an effort to advance silicones for LiDAR and related automotive sensor applications, Shin-Etsu Silicones of America, Inc. (SESA), a U.S. subsidiary of Shin-Etsu Chemical Co. Ltd., has developed a UV-activated, dual-cure silicone series that includes the KER-4410 and KER-4440 products as focal points. Silicones contain compounds that feature a main chain of siloxane bonds that provide distinct advantages over epoxy alternatives, including heat stability, cold resistance, stress releasing, no curing shrinkage, and addition/radical polymerization.

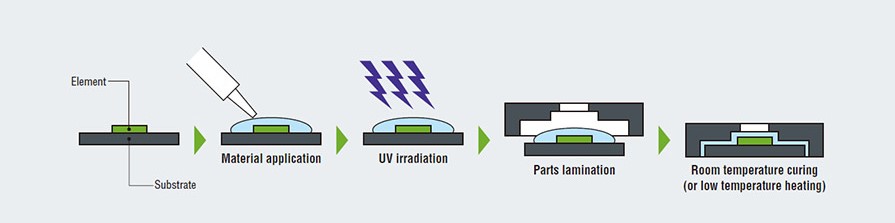

Once the silicone adhesive is applied and exposed to UV, the sensors or components are placed on the board and other board processes can be conducted in parallel (see Figure 1). This dual-cure system saves processing time, requires no need for ovens at high temperatures, doesn’t shrink during curing (vs. epoxies), and delivers no added stress.

Figure 1. The dual-cure system saves processing time, requires no need for ovens at high temperatures, doesn’t shrink during curing (vs. epoxies), and delivers no added stress.

The series’ UV-activated cure silicone has a time lag from UV irradiation to the start of curing that is different for each product. The UV addition type is irradiated with UV light and then cures fully at room temperature or with elevated temperatures.

The adhesives’ curing shrinkage rate is less than 0.1%, which is small compared to general organics such as acrylic and epoxy UV resin. KER was coated and cured around a copper substrate in a 2-mm thickness and showed no signs of warpage.

KER-4410

Key properties of KER-4410 include: hardness, A10; tensile strength, 2.3; elongation, 350; and appearance, colorless and slightly cloudy. After UV irradiation, it takes 10-15 min at 23°C until the KER-4410 material starts to cure. It is also possible to bond the base material after UV irradiation, making the adhesive suitable for bonding non-transparent materials such as metal to overcome shadow-cure areas. Heat treatment also reduces curing time.

While KER-4410 features a long open time (15-20 min), the specific open time depends on the UV-integrated light intensity. The recommended open time is within 15 min for 3,000 mJ/cm2 and within 5 min for 12,000 mJ/cm2.

KER-4440

Key properties of KER-4440 include: hardness, A43; tensile strength, 6.1; elongation, 430; and appearance, creamy white and translucent. KER-4440 gels in a short time (within a few minutes) after UV irradiation, so it is recommended to perform UV irradiation after placing the substrate.

By changing the UV irradiation conditions, it is also possible to slightly adjust the curing start time. When laminating after UV irradiation, curing should be performed before the gelation starts. After UV irradiation, KER-4440 fully cures at 23˚C in one day; however, the adhesive strength will be further improved by heat treatment at 80˚C for 1 hr.

“Shin-Etsu’s depth of experience and knowledge as a silicone material leader in the automotive sensor market has provided a spring board for us to launch the KER- 4410/4440 series across a myriad of key LiDAR and ADAS market segments,” said Chad Kobylanski, SESA’s automotive segment manager. “We strive to be at the forefront of this by evolving essential products in this line, and developing solutions for these unique and demanding applications.

For more detailed information, visit www.shinetsusilicones.com.

Note: Images courtesy of Shin-Etsu Silicones of America, Inc.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!