Columns

Ask Dr. Dave

We want to bond sheets of polystyrene foam to steel and to wood. What adhesives would you recommend that will be effective and safe to use?

Read More

Ask Dr. Dave

Vibration- and Shock-Resistant Adhesives

Which adhesives can resist serious vibration and shocks?

October 20, 2021

Strategic Solutions

Assembly with Adhesives

Three key steps must be undertaken when considering the use of adhesives in assembly operations.

October 11, 2021

From the Editor

Moving the Adhesives and Sealants Industry Forward

The adhesives and sealants industry relies heavily on distributors for far more than simply raw materials and chemicals shipments.

September 23, 2021

Ask Dr. Dave

Bonding Fluoroplastic Parts to Metals

We manufacture PTFE and other fluoroplastic parts. We have been requested to make parts that can be bonded to metals. Is there a good adhesive, some sort of additive to the PTFE, or a surface treatment that we can use?

September 21, 2021

Ask Dr. Dave

Adhesives for Fiberglass Bonding

What are the best adhesives for bonding fiberglass components?

July 20, 2021

Ask Dr. Dave

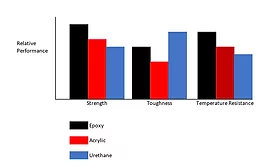

Moisture-Sensitive Urethane Adhesives and the Pros and Cons of Epoxies

Dr. Dave tackles two questions this month, one related to package stability for moisture-sensitive urethane adhesives, and the other regarding epoxy adhesives.

June 15, 2021

From the Editor

Adhesives and Sealants Help Brands Achieve the Complete Package

Brands are exploring sustainable packaging as a means of increasing their appeal to environmentally conscious consumers.

May 21, 2021

Strategic Solutions

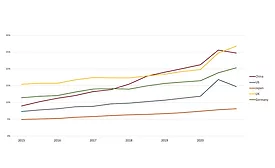

COVID-19 Impact on Global Shipping and Packaging Dynamics

The continued transition away from brick-and-mortar to ecommerce brings demand for packaging innovations that enable faster delivery and better content protection from shock or temperature variations.

May 19, 2021

Ask Dr. Dave

Packaging Moisture-Sensitive Sealants

Can you recommend suitable materials for packaging a sealant that is sensitive to atmospheric moisture? Additionally, we can do accelerated humidity testing of filled packages, but how do we correlate these with shelf life?

May 17, 2021

Keep the info flowing with our newsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing