Adhesives & Sealants Industry Top Stories

Case Study

For processes such as tape manufacturing, a recuperative thermal oxidizer specially designed for high levels of silicone may be most effective.

Read More

Ask Dr. Dave

How can we ensure full cure when using a UV-cured coating/adhesive on irregularly shaped parts?

Dr. Dave shares tips on avoiding blind areas that do not cure completely on irregularly shaped parts.

April 23, 2020

Combatting COVID-19: Manufacturers Keep Stepping Up

Manufacturers are continuing to address the unique needs of the pandemic through a number of different initiatives.

April 22, 2020

Advancing Adhesives

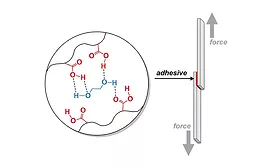

Making Adhesives Tougher with Weaker Bonds

Researchers have found that adding sacrificial weak bonds can improve the toughness of an adhesive system.

April 21, 2020

Advancing Adhesives

Legislation on GLYMO Will Shape Packaging in 2020

Epoxy silanes like GLYMO and GLYEO are adhesion promoters used in food packaging, but safety issues have prompted the development of new alternatives.

April 21, 2020

Strategic Solutions

Driving Innovation by Collaborating with Others: Know Your Areas of Focus

Scouting for collaboration opportunities outside your company is a process that begins with defining and prioritizing the market's needs in a way that anyone unfamiliar with your business can understand.

April 20, 2020

Advancing Adhesives

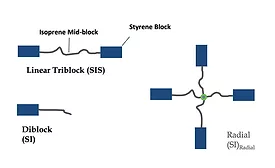

Elastic Strand Bonding without the Use of End-Block Resins

Styrene-isoprene-styrene polymers can be used to eliminate the need for end-block resins in elastic laminate bonding applications.

April 16, 2020

Real-Time Monitoring of Adhesive and Sealant Properties

The correct adjustment of flow characteristics of sealants and thermosetting adhesives is crucial to their performance in automated, high-speed production environments.

April 14, 2020

How is COVID-19 Impacting the Adhesives and Sealants Industry?

Adhesives and sealants companies are facing major challenges on a number of fronts due to the COVID-19 pandemic, but they can take steps to navigate through the crisis.

April 10, 2020

How Do Stabilizers Improve Durability in Adhesives and Sealants Formulations?

Raw materials in adhesives and sealants formulations are often protected from degradation by suitable stabilizer packages or through appropriate packaging.

April 9, 2020

Keep the info flowing with our newsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing