Adhesives & Sealants Industry Top Stories

Ask Dr. Dave

Dr. Dave shares insights regarding challenges and options for adhesive applications involving water immersion.

Read More

Meeting Modern Challenges in Bonding to Automotive Thermoplastic Olefin Plastics

Thermoplastic olefin plastics present unique challenges for pressure-sensitive adhesives in automotive applications.

February 17, 2020

Strategic Solutions

Evolving Hybrid Adhesives

This first installment of a two-part series highlights the value proposition of today's adhesive chemistries and curing methods to high-value end-use markets.

February 13, 2020

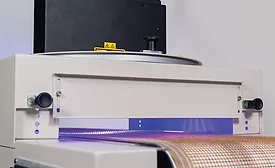

Manufacturing Conversion: Transitioning from Conventional UV to LED Curing

While the process steps in a UV LED manufacturing conversion are slightly more involved than a direct-swap mercury replacement, the benefits are often significant and well worth the time and effort.

February 10, 2020

From the Editor

Sourcing Solutions for Raw Materials and Chemicals

The goal of our annual Raw Materials, Chemicals, Polymers and Additives Handbook is to help you source the materials you need to succeed.

February 6, 2020

2020 Raw Materials and Chemicals Roundtable

In response to continued uncertainties, raw materials and chemicals suppliers are undertaking a number of strategic initiatives.

February 3, 2020

3M Announces 2019 Financial Results, Additional Restructuring Efforts

3M has initiated a restructuring that will reduce approximately 1,500 positions, spanning all business groups, functions, and geographies.

January 29, 2020

Product Profile

Optimized Dispensing for Electronics and Automotive Assembly

An optimized dispenser series enables the dispensing of adhesives and sealants in small quantities for electronics, automotive, and similar applications.

January 29, 2020

Ask Dr. Dave

What is your recommendation for bonding small ceramic tiles vertically to a fireplace surround?

Dr. Dave discusses the relative merits of various adhesives for tile fireplace surrounds, plus the effect chlorinated water may have on epoxies.

January 23, 2020

Surface Treatment with Atmospheric Plasma

The chemistry of an atmospheric plasma surface treatment must be adopted to the targeted process.

January 21, 2020

Keep the info flowing with our newsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing