TOYOCHEM CO., LTD.: Flexible EMI Shielding Film for High-Speed Flexible Printed Circuits

According to Toyochem, TSS510-HF addresses the needs of today’s electronics designers for improved shielding performance for the transmission of high-frequency signals and for high flexibility so circuits do not break when bent.

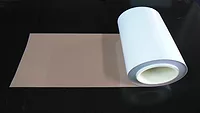

Toyochem Co., Ltd., a member of the Toyo Ink Group, has launched a flexible electromagnetic interference (EMI) shielding film, LIOELM™ TSS510-HF, designed to meet the performance requirements of 5G flexible printed circuits (FPCs). According to the company, TSS510-HF addresses the needs of today’s electronics designers for improved shielding performance for the transmission of high-frequency signals and for high flexibility so circuits do not break when bent.

The flexibility of FPCs has seen their adoption in a wide range of industrial and consumer electronic devices. As the mobile world transitions from 4G to 5G, the demand for higher performance flex circuits is expected to grow in line with demand for more advanced smartphones and 5G/IoT devices, including camera flex circuits, display flex circuits, and wearable devices. While copper plating technology is typically used in the manufacturing of FPCs to absorb radio and other EMI waves, copper is not ideal for applications that require high flexibility, often cracking when the circuit is bent or folded, or burring during the die-cutting process.

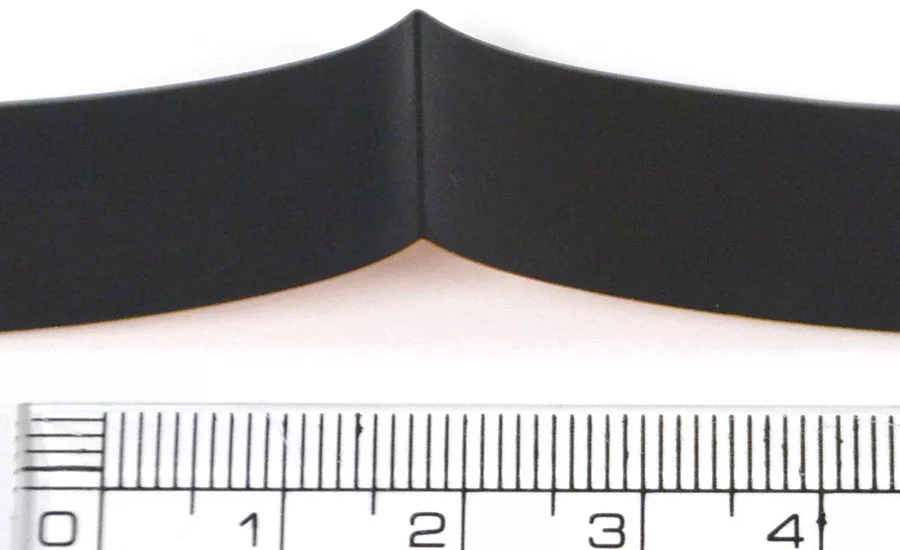

Addressing these challenges, Toyochem reports that its technicians in Japan engineered the TSS510-HF shielding film to exhibit extraordinary flexibility, with no cracking even after bending the film 20 times at a 180˚ angle, 2-kg load. Toyochem was able to achieve these advances by using a flexible and conductive urethane resin in place of traditional copper wiring as the EMI shielding material. The resin was first dispersed with a conductive filler, which generates a resin composite with enhanced compatibility between film flexibility and tensile strength. The optimized film structure enabled the company to solve the cracking and burring issues associated with copper foil shields.

Performance tests of the TSS510-HF shielding film reportedly demonstrated reduced transmission loss at the -6.5 dB level at 15 GHz, relative to -8.5 dB for conventional shielding films. Shielding effect testing generated values greater than 70 dB at 15 GHz, compared to 60 dB for conventional types, thereby making the TSS510-HF suitable for use in FPCs in the high-frequency band. Moreover, the company reports that the film’s bendability offers FPC design engineers unlimited freedom in the shaping of flexible electronic devices.

For more information, visit www.toyo-chem.com/en.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!