Product Profile

B-Staged Epoxy Meets Airbus Standards for Flame Retardancy and Toxicity

Adhesives and sealants must meet stringent requirements for use in aircraft and other applications.

Master Bond EP36FR is a specialized one-part epoxy that meets Airbus specifications for toxic gas emissions per AITM 3.0005, Issue 2 in the flaming mode and Section 7.4 of ABD0031, Issue F. It also passes the 12-sec vertical burn test per AITM 2.0002B and Section 7.1.2 of ABD0031, Issue F. EP36FR uses a non-halogenated filler.

“These Airbus ratings are not just relevant for manufacturing aircraft components, but they are also considered to be among the most stringent of certifications for flame retardancy and toxicity,” said Rohit Ramnath, senior product engineer. “They [the ratings] serve as a good starting point for various composite applications across the aerospace, marine, transportation, electrical, and automotive industries.”

According to Master Bond, EP36FR withstands rigorous thermal cycling, as well as thermal and mechanical shocks. It has excellent high temperature resistance up to 500°F, despite a low glass transition temperature of 95-100°F. This system maintains its toughness or hardness across a wide temperature range and is ideal for potting, encapsulation, sealing, and coating applications. The hardness values at 212°F and 300°F are in the 20-30 Shore D range.

The EP36FR formulation is B-staged, meaning it is a solid at room temperature and must be heated in a forced air or convection oven to transform it to a liquid at around 200°F. This feature allows it to be reused when it resolidifies at room temperature, provided it has not been cured. After liquefying the product at 200°F and applying it on the substrates in the application, it needs to be heat cured for 2-3 hrs at 350°F.

Master Bond EP36FR reportedly bonds well to metals, composites, glass, and many plastics. The product is available in ½-pint, pint, quart, and 30-g preforms.

Testing Details

During the vertical ignition test (conducted in accordance with Airbus AITM 2.0002B, Issue 2 for specification ABD0031, Issue F, Section 7.1.2), casting specimens are exposed to certified pure bottled methane for 12 sec. Measurements include how quickly the flame is extinguished and how far it spreads. Airplane interiors that might be tested for the 12-sec vertical burn test include carpeting and other floor coverings, upholstery, seat cushions, and air ducting.

Another Airbus test involves the optical density of smoke generated by solid materials (conducted in accordance with AITM 2.0007B, Issue 3 for specification Airbus Document ABD0031, Issue F, Section 7.3.2). In this test, the epoxy casting is exposed to a flame for 60 sec, after which a successful result would show that the smoke being generated is below the threshold of 200 specific optical density (Ds). This Airbus test may be used on interior wall panels, aircraft doors, and stowage compartments.

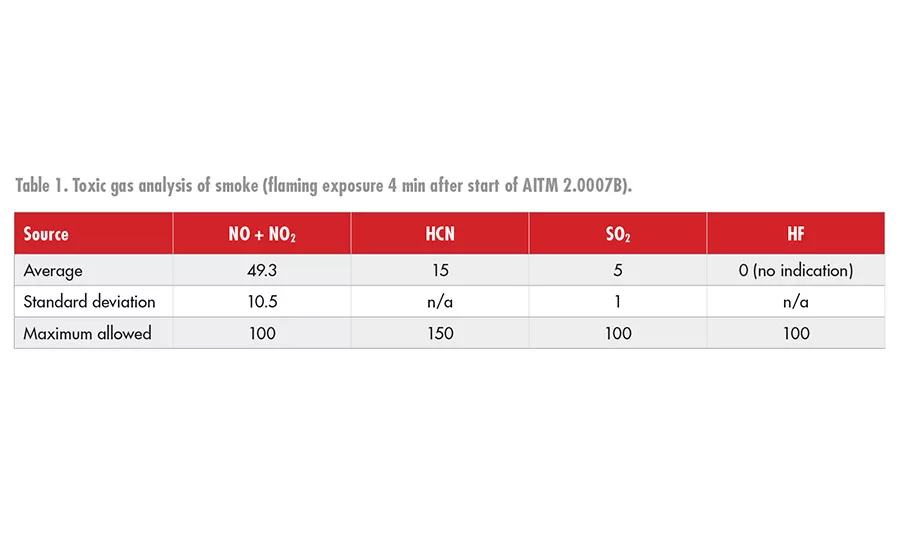

An analysis is also performed on the toxic gas of the smoke that was generated. At the end of the smoke test, 4 min after initiation, the specimen is tested for toxicity to certain reactive gases, like carbon monoxide, hydrogen chloride, nitric oxides, sulfur dioxide, hydrogen cyanide, and hydrogen fluoride. Table 1 lists the acceptance criteria for toxicity specified by the Airbus test, ABD0031 Issue F, Section 7.4 per AITM 3.005, Issue 2.

For more information, visit www.masterbond.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!