Electric Vehicle Market Advances Generate Adhesive Technology Innovations

As the electric vehicle market evolves and develops, adhesive manufacturers create new technologies to meet these needs.

The use of adhesives in electric vehicles (EVs) is even more widespread than in conventional automobiles. In both types of vehicles, adhesives offer many advantages, including ease of use compared to welding, environmental resistance, sealing, distributing stress, and joining dissimilar materials.

The advantages of adhesives specific to EVs include weight reduction, thermal conductivity, electrical insulation, friable adhesives, bonding composites, and the ability to bond low-surface-energy (LSE) plastics. As the EV market evolves and develops, adhesive manufacturers expand product lines and create new technologies to meet these needs. The drive to create vehicles with a more extensive range fuels the innovation.

Weight Reduction and Thermal Conductivity

Adhesives have been used for weight reduction in conventional vehicles for decades to reduce fuel usage. In EVs, weight reduction is even more crucial to minimize power consumption and increase the vehicle’s range on a charge. Although the primary drivers for weight reduction are related to battery life in EVs, the lighter weight makes handheld battery appliances such as vacuums and drills more ergonomic and easier to use.

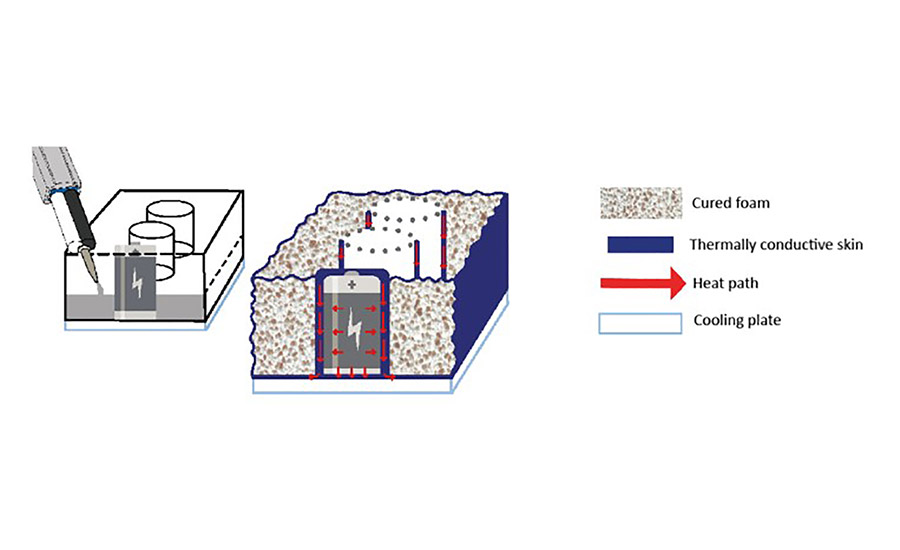

New patent-pending technology is available to reduce weight in battery packs while providing thermal management. The material expands to form a lightweight foam structure that fills all the battery pack’s free space as it cures (see Figure 1). When it expands in the closed container, compression creates a highly conductive skin that efficiently transfers heat to the cooling plate. The dual structure of the lightweight foam and hard skin in close contact with the batteries, case walls, and cooling plate creates a thermal bridge for heat conduction and dissipation.

Figure 1. New patent-pending technology expands to form a lightweight foam structure that fills all the battery pack’s free space as it cures.

The open-cell foam is low density, as low as 0.5 g/cm3, and has a thermal conductivity estimated to be approximately one-third of the skin. The skin is highly conductive, up to 4 W/m•K or higher, depending on the filler. Faster thermal dissipation allows for quicker charging, which is vital, particularly at service station charge points.

In addition to being lightweight and thermally conductive, the foam is electrically insulative and has better vibration absorption than a solid. It is also easier to dismantle than a solid-filled system, reducing the battery recycling costs.

The technology is customizable to meet the exacting requirements of each battery manufacturer. A scooter or robotic vacuum cleaner battery will have drastically different sizes, shapes, capacities, thermal management needs, and dielectric requirements than a battery for an electric automobile. As such, the technology can be altered to suit the specific needs of each battery to optimize performance and extend the range.

Friable Adhesives

Friable adhesives are uniquely used in EVs as a pyrotechnic disconnect. In the event of a collision, a charge is detonated to detach the battery from the car’s electronics system. This disconnect helps to prevent fire, short circuits, or electrifying the car and frazzling the occupants and any rescue workers.

The adhesive must be friable; in other words, it must go up in a poof of vapor so it doesn’t become a missile that could penetrate the battery or other car parts, just as an airbag detonator mustn’t injure the vehicle passengers. UV-curable adhesives that contain a secondary anaerobic cure mechanism to ensure cure in shadowed areas are used to form these attachments.

Hydrogen Fuel Cells

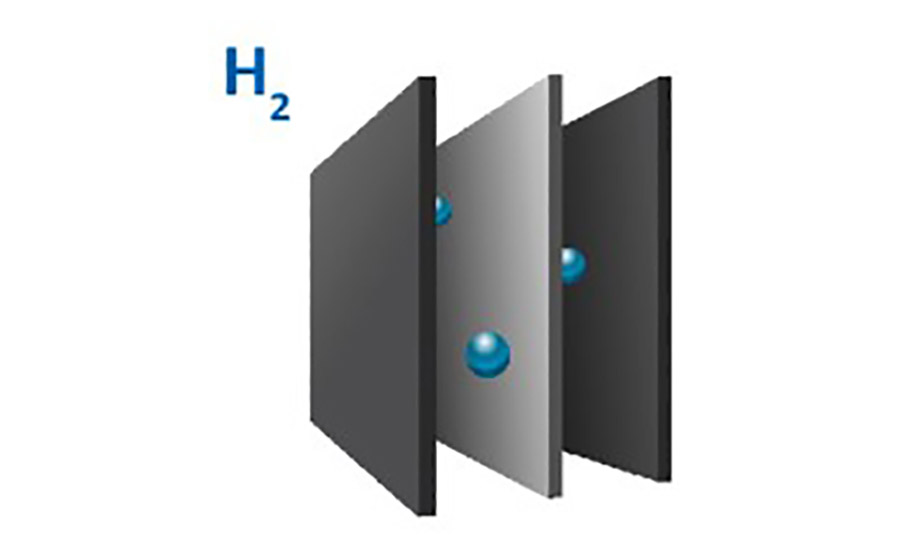

Graphite is used to make slides and lubricants, so it is not the easiest material to bond. Single-component epoxy adhesives that cure with heat to form strong bonds to graphite and other substrates have been developed for use in hydrogen fuel cells (see Figure 2).

Figure 2. Single-component epoxy adhesives have been developed that cure with heat to form strong bonds to graphite and other substrates in hydrogen fuel cells.

Battery Housing Bonding

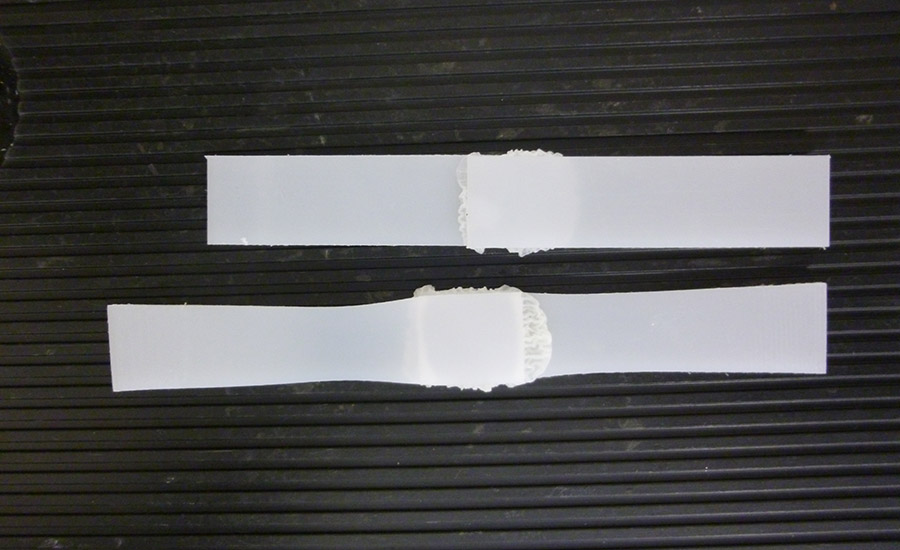

Battery housings are often made of LSE plastics such as polypropylene that are difficult to bond. Specialty structural acrylic adhesives bond LSE plastics without primers or surface pre-treatments. As shown in Figure 3, the bonds are so strong that the plastic stretches and deforms before the bond gives way. These adhesives have excellent chemical and water resistance, ensuring a good seal that withstands impact and vibration.

Figure 3. Lap shear tests illustrate the ability of specialty structural acrylic adhesives to bond LSE plastics.

Fire-Retardant Adhesives

By now, we’ve all heard of lithium-ion battery fires in phones and hoverboards. It is no wonder that EV battery manufacturers are looking for fire-retardant adhesives, and those designed to meet the UL94 V-0 flammability standard are in high demand.

Fire-retardant, thermally conductive modified epoxy adhesives are popular for bonding battery modules. They can provide flexibility to absorb impact and vibration forces while being electrically insulating and intumescent.

Temperature-Resistant Adhesives

A common thread throughout all battery adhesive discussions is heat, temperature, and fire. Heat is a hot topic for battery manufacturers: from adhesives that burn to those that won’t, and from adhesives that conduct heat to those that resist heat. The temperature resistance of various adhesive technologies is listed in Table 1, with an average and high rating for each.

| Chemistry | Standard Grade | High-Temperature Grade |

|---|---|---|

| Anaerobic | 300°F (150°C) | 450°F (230°C) |

| Cyanoacrylate | 185°F (85°C) | 480°F (250°C) |

| Epoxy (1-part) | 350°F (180°C) | 570°F (300°C) |

| Epoxy (2-part) | 175°F (80°C) | 570°F (300°C) |

| Structural acrylic (no mix) | 300°F (150°C) | 390°F (200°C) |

| Structural acrylic (2-part) | 250°F (120°C) | - |

| UV curable | 250°F (120°C) | 300°F (150°C) |

What’s Next?

The best teachers are those that push us past our comfort level to innovate, and the EV battery industry continues to be a great teacher for adhesives manufacturers. Developing the adhesive technology is only the first step. Tailoring the technology to suit each manufacturer’s requirements spurs even more innovations.

Some of those innovations are specific to e-mobility, but the industry prompts the development of new technologies for other vehicle assembly applications. Examples include electric motor magnet bonding and camera lens bonding. Other innovations are specific to bonding substrates used within the battery and vehicle market, such as PBT, glass-filled Nylon, and other difficult-to-bond materials.

Assembly applications aren’t the only areas of growth for adhesive technology. Disassembly applications such as adhesive developments that drastically reduce the extremely high costs of battery recycling are another area of adhesive technology growth.

For more information, visit www.permabond.com.

Note: Images courtesy of Permabond.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!