Adhesive Systems Optimize Heat Dissipation in EV Batteries

Liquid adhesive systems offer an alternative to silicone-based pads to dissipate heat generated in electric vehicle battery cells.

Wevo adhesive systems reliably dissipate the heat generated during the charging process from the battery cells to the heat sink. (Image source: © Bildwerk – stock.adobe.com)

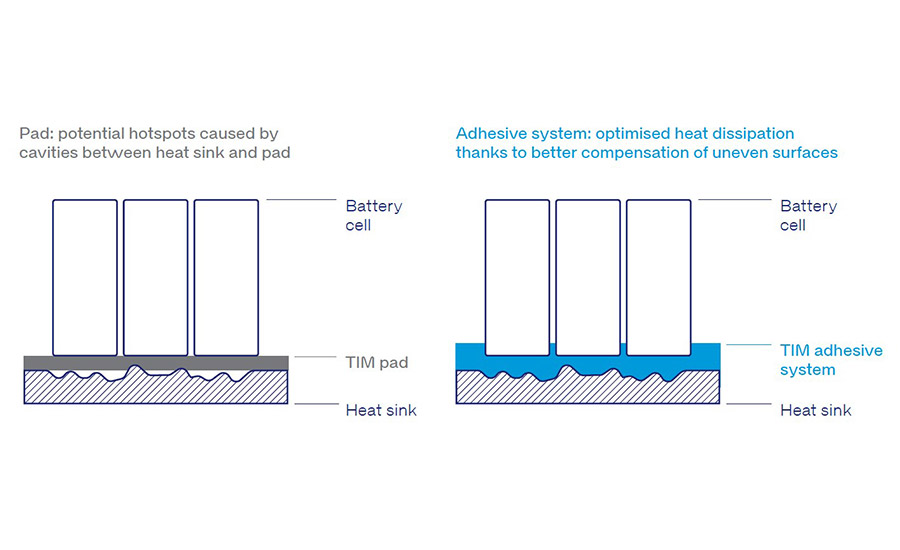

High temperatures are generated in the battery cells of electric vehicles (EVs) during charging, and these have to be dissipated. Until now, this has mostly been achieved by inserting silicone-based pads between the cells and the cooling system. However, the manufacturing process of batteries is increasingly demanding that thermal interface materials (TIMs) with adhesive properties be used – something silicone pads are not able to provide. Liquid adhesive systems developed by WEVO-CHEMIE GmbH offer better surface wetting and can also be used as structural adhesives. In addition to the optimized heat dissipation, these customizable polyurethanes also open up new possibilities in the design process.

The ongoing upgrade of the system voltage of EVs from 400 V to 800 V is leading, among other things, to an increase in the efficiency of the battery charging process. However, this results in high temperatures – also in the battery cells. TIM pads no longer provide adequate heat dissipation in these cases. That is because the inlaid solutions that are inserted between the cells and the cooling system do not fully compensate the uneven surfaces of the cells and cooling system (see Figure 1). This can lead to hotspots and damage to the cells.

Heat dissipation in electric vehicle battery cells

What’s more, insertion solutions such as pads can no longer satisfy the complex geometries of modern battery design concepts. The customized liquid adhesive systems developed by Wevo are the perfect solution for the job. They are flexible and are applied directly to the cooling system – three-dimensional if required – and pressed together with the battery cells. This prevents air voids from forming and ensures immediate dissipation of the generated heat to the cooling system.

Properties Meet Latest Battery Designs

Wevo has set the thixotropy and therefore the rheological properties of these adhesive systems so they can be applied as a vertical bead that doesn’t collapse, even if the components are tilted or rotated as part of the manufacturing process. At the same time, the corresponding special fillers ensure that the viscosity of the potting compound doesn’t rise disproportionately to the thermal conductivity. This enables trouble-free processing in standard dosing systems despite the compound’s high thermal conductivity. The reactivity of the materials is individually adjusted to the customer’s particular process – for fast downstream processing and short production cycles.

These products can also be used as structural adhesives for durable and dimensionally stable bonding applications. This makes it easier for battery manufacturers to overcome challenges they come up against in the design process. That is because the polyurethane adhesives make it possible, for example, to dispense with certain screwed connections, helping to reduce the overall weight of the battery and increase the range it offers.

Learn more about Wevo adhesive systems at www.wevo-chemie.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!