Home » acrylics

Articles Tagged with ''acrylics''

Avery Dennison reports that its new Core Series was designed to address the majority of converters’ bonding needs.

Read More

Polythioether Advances Provide New Formulating Options for Adhesives, Sealants, and Coatings

A colorless, toughening, and chemically resistive polythioether has been developed for the formulation of adhesives, sealants, and coatings.

January 2, 2020

Ask Dr. Dave

What is the difference between thermoplastic and thermoset adhesives?

Thermoset and thermoplastic adhesives can be differentiated by whether or not they soften on heating.

November 18, 2019

PANACOL: Biocompatible Acrylic Adhesive

Panacol’s Vitralit 7311 FO is a low-viscosity, transparent acrylic adhesive that cures under UV or visible light.

November 12, 2019

Ask Dr. Dave

What cure systems are available for UV adhesives?

UV adhesives can be cured using free radicals for acrylic adhesives or cations for cationic monomers.

October 24, 2019

What Are Structural Adhesives?

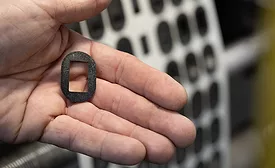

Structural adhesives can offer stronger bonds than mechanical fasteners.

October 10, 2019

Sun Chemical to Highlight Pigment and Resin Technologies at ABRAFATI 2019

Visitors to Sun Chemical’s booth (Aisle D, Stand 2) will learn about key investments in product line expansions to meet the needs and trends of the marketplace.

October 1, 2019

Dow Unveils Pressure-Sensitive Solutions for Paper and Film Label Applications at Labelexpo Europe

Dow reports that the new offering expands its portfolio for pressure-sensitive label applications with solutions that address key market trends.

September 30, 2019

Ask Dr. Dave

How can acrylic adhesives be used at very high temperatures?

Dr. Dave discusses steps that can be taken to ensure that acrylic adhesives perform as expected in high-temperature applications, such as automotive.

September 3, 2019

Ask Dr. Dave

What are the best adhesives and sealants to use for home repairs and craft projects?

Dr. Dave details adhesive and sealant selections for various consumer applications.

August 26, 2019

Keep the info flowing with our newsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing