Home » electric vehicles

Articles Tagged with ''electric vehicles''

From the Editor

From complex electronics assemblies to lightweighting and beyond, the incorporation of adhesives and sealants in transportation applications is expanding.

Read More

Silicone Adhesives for Lifetime Performance in Vehicle Electrification and Autonomy

Module joint design, adhesive selection, substrate choice, and combined mechanical and environmental stresses in the field all impact the longevity of the protective seal on a vehicle's electronic part.

January 27, 2021

Adhesives in Automotive Assembly

Advanced sealants and adhesives in vehicle assembly effectively and safely address key applications that have traditionally employed mechanical fasteners while adding design freedom to today's modern vehicles.

September 29, 2020

Five Key Trends Shaping the Future of Tech Innovation Across All Industries

The five trends that are shaping the post-COVID-19 future include infection prevention, remote commerce, improving resiliency, greater agility, and macroeconomic impacts.

September 14, 2020

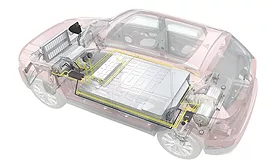

Electric Vehicles and the Growing Significance of Adhesives and Sealants for Battery Assembly

Adhesives, sealants, and heat transfer materials used in battery assembly operations will find myriad opportunities in the exciting electric vehicle market.

March 9, 2020

ADHESIVE AND SEALANT COUNCIL: Adhesives and Sealants in Electric Vehicles White Paper

According to the ASC, the white paper provides ASC members visibility into market opportunities and growth potential in the electric vehicle (EV) market.

December 17, 2019

Adhesive Technologies Help Electric Vehicles Go the Distance

New adhesives, sealants, and foams can address the thermal and weight challenges of modern high-voltage vehicle batteries.

October 1, 2019

Advancing Adhesives

Sealing Solution for Electric Vehicles

Structural adhesives for battery pack assemblies in electric vehicles help ensure long-life components operation.

September 1, 2018

Keep the info flowing with our newsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing