Adhesive Technologies Help Electric Vehicles Go the Distance

New adhesives, sealants, and foams can address the thermal and weight challenges of modern high-voltage vehicle batteries.

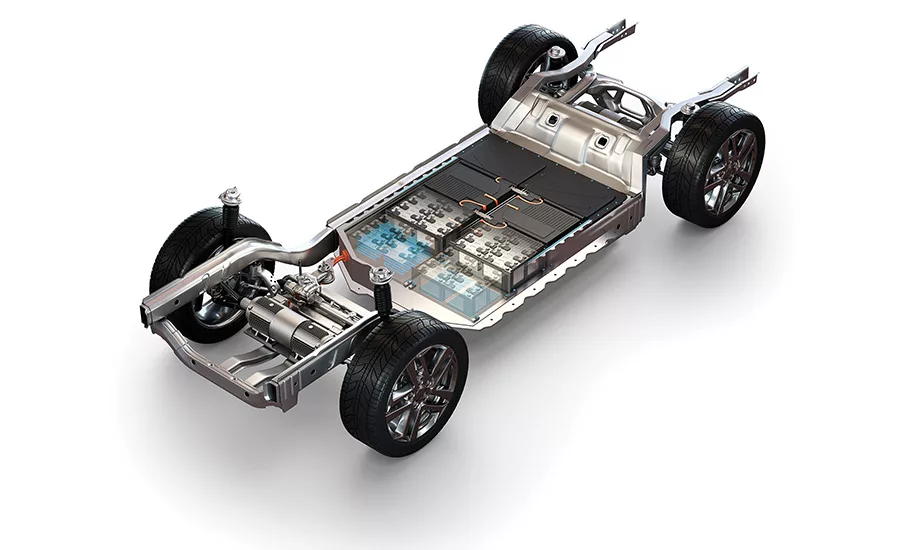

Figure 1. High-voltage battery box in the structure of an electric vehicle. (Courtesy of Atlas Copco; originally published at www.springerprofessional.de.)

The desire to reduce vehicle emissions, especially in densely populated areas, is driving the replacement of combustion engine-powered cars with electrical vehicles. Most OEMs have introduced fully electrically driven cars to the market in recent years, and they will continue to do so to a great extent in the near future. The prospect for OEMs and Tier-1s in this new segment of the automotive market is extremely positive. Fuel cells as an option for alternative drives are discussed, but batteries seem to be the favored solution in spite of incomplete infrastructure in many countries.

High-voltage batteries are engineered to be vehicle specific or in a building block for passenger cars. The high volume of passenger cars allows customized solutions; alternatively, a platforms concept is applied for the battery analog to other drivetrain components. Delivery trucks, buses, trains, and construction vehicles are produced in much smaller volumes. Modular batteries are the preferred solution here.

Thermal management is crucial in the battery design, as the cells will only operate reliably, efficiently, and long term when kept within a tight temperature band. Cells can easily reach temperatures of 80°C during charging and discharging, and the heat created needs to be dissipated away from the cells. The weight of the battery is also an important criterion; lightweight components are crucial when engineering an electrical vehicle. New adhesives, sealants, and foams can address the thermal and weight challenges of modern high-voltage vehicle batteries.

Insulating the Cells

While controlling and dissipating the heat generated during the charging/discharging cycle, silicone foam can be used to isolate the cells from each other to delay or prevent thermal runaway. Silicones are characterized by excellent temperature resistance and are good thermal insulators when foamed. Therefore, the propagation of local overheating can be greatly reduced.

At the same time, the insulation contributes to the thermal stabilization of the battery and thus preserves the performance when temperatures are low. Moreover, the low density of the insulation materials minimizes battery weight.

Dissipating the Heat

Many different technologies are available to thermally bridge from the cells to the battery cage bottom. Traditionally, thermally conductive pads have been used. They work well for low-volume production and for smaller batteries. However, high volumes and large batteries dictate the use of thermally conductive, elastic, paste-like gap fillers. Among other benefits, integration into a production line with mixing and dispensing equipment is easier with these materials and lowers the probability of damaging the modules when pressure is applied during the assembly process.

The silicone-based gap fillers used for years in the electronics industry are now complemented by one- or two-component polyurethane gap fillers that partially contain less abrasive fillers, which also protects the pumps and dispensing systems. In most applications, a heat exchanger is needed to keep the temperature of the cells within a defined range during the charging and discharging cycle; the heat exchanger is mounted on the bottom of the battery cage.

The alternative to integrating the cooling into the battery cage or to soldering the heat exchanger is a thermally conductive adhesive. However, it has to be considered that the heat conduction of the adhesive is only part of the total heat transfer. Housing materials, coolant temperature, and the conductivity of the other materials are important parameters to consider.

Designing the Battery Cage

In passenger cars, the battery is typically mounted on the floor of the vehicle, making the construction crash relevant (see Figure 1). When the battery is mounted, crash safety is required from the OEMs in order to protect the electric vehicle passengers.

Adhesive technology constitutes a good alternative to traditional metal construction, particularly when stress-free, non-deformable, and dimensionally stable components must be produced. Structural adhesives have been used in car body engineering for many years and contribute positively to crash performance. The transfer of this technology to battery cages is possible with shear strengths of more than 10 MPa.

Apart from specifying the physical properties, many other considerations are necessary before selecting the adhesive. The components and their tolerances, surface cleaning, and pre-treatment must be considered here. The respective advantages and disadvantages of the various adhesive systems are listed in Table 1.

Customer requirements on the serviceability of the battery are decisive for selecting the cover seal. If frequent service is expected, the cover can be mechanically fastened with a foam or elastomer seal. The seal should firmly adhere to the lid and have a good compression set. Various technologies are available to achieve this, including mechanically foamed polyurethanes or two-component silicones such as elastomers or foams (see Table 2).

Adhesive solutions are also available if the battery is only rarely—or never—opened. These include a fastening analog to the windshield, which can be cut open and re-glued in the case of needed repair, or a permanent adhesion of the lid.

For more information, visit www.bm-chemie.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!