Meter/Mix/Dispense

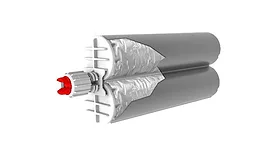

Introduction to Static Mixing in Laminar Flows

The first of a three-part series on static mixing, this article focuses on the different mixing principles in laminar mixing and the typical mixer geometries derived from them.

September 13, 2023

Identifying the Best Pumps for Corrugated-Box Manufacturing

Air-operated double-diaphragm (AODD) and internal gear pumps are used for the handling and transfer of corn-starch glue in corrugated-box manufacturing.

June 27, 2023

Keep the info flowing with our newsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing