Adhesives & Sealants Industry Top Stories

As continued research and development races to meet the growing appetite for sustainable adhesives, manufacturers must also push innovations in processing that reduce both waste and energy consumption.

Read More

Ask Dr. Dave

Surfactants and Sustainability

We hear that some surfactants have been banned. Is it a problem in the adhesives and sealants that we manufacture?

August 28, 2020

Exploring Sausage Packages for Commercial and DIY Mastics

Many mastic users are either unaware that the sausage package option is available or they find it is not available in the brand they prefer.

August 25, 2020

Bio-Based Materials for Adhesives and Sealants: The Sustainability Revolution is Here

Fostering the bio-economy requires new technology that pushes the boundaries of bio-based performance.

August 21, 2020

From the Editor

Twice as Nice

This issue of ASI brings you our annual Distributor Directory, as well as the ever-popular ASI Top 20 listing of the world’s leading adhesives and sealants manufacturers.

August 19, 2020

Strategic Solutions

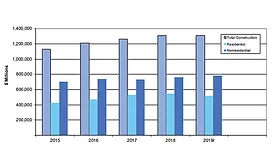

Market Dynamics for North American Sealants

Through 2019, the building and construction market was a sealants volume leader, followed by assembly operations and transportation.

August 17, 2020

2020 ASI Top 20: Leading Global Manufacturers of Adhesives and Sealants

We targeted sales figures (and other details) for finished adhesives and sealants, as well as related products, to develop the ASI Top 20 ranking of leading adhesive and sealant manufacturers.

August 12, 2020

Navigating the Adhesive and Sealant Industry through the COVID-19 Pandemic

The Adhesive and Sealant Council is supporting members during the coronavirus crisis with communication, education, and engagement opportunities.

August 10, 2020

Container Labeling for Adhesives and Sealants

Proper selection of label and labeler type enables the efficient application of labels on virtually every container shape used in the adhesives and sealants industry.

August 6, 2020

Ask Dr. Dave

Solvent-Based Adhesives

I was brought up using solvent-based adhesives, but they don’t seem to be as common these days. Is it just a safety issue? Are any of these adhesives still available?

August 4, 2020

Keep the info flowing with our newsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing