HENKEL: Thermal Interface Material for Digital Applications

Henkel recently announced the commercialization of its latest gel thermal interface material (TIM), BERGQUIST® LIQUI FORM TLF 10000. The one-part, high thermal conductivity dispensable gel is designed to provide robust heat transfer for high-power electronic components, improving operational efficiency and extending lifetime system reliability.

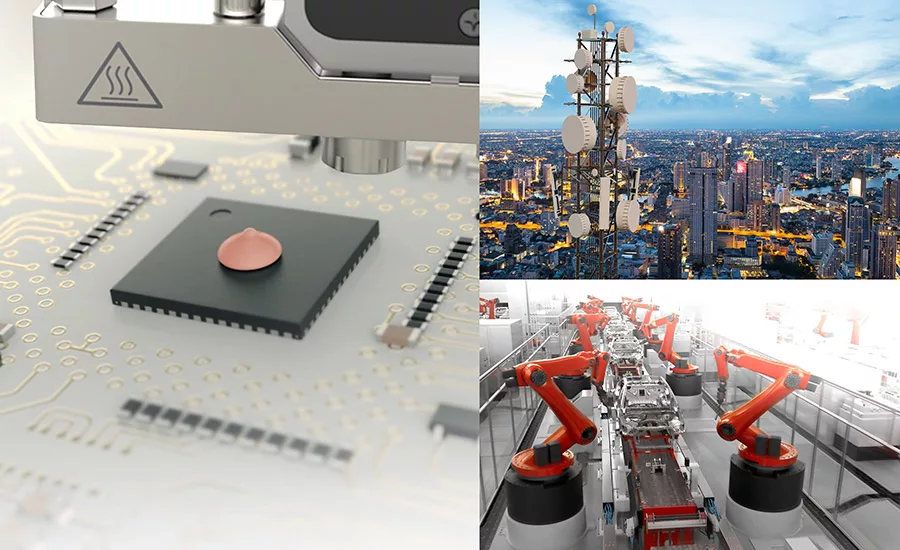

Larger, higher power devices such as application-specific integrated circuits (ASICs) and field-programmable gate arrays (FPGAs) are the norm in 5G telecom infrastructure gear, data center switches, routers, and servers, as well as electric vehicle (EV) infrastructure and industrial automation electronics. As component density and complexity increase in response to faster data processing and digitalization requirements, higher wattage thermal output must be controlled to deliver dependable performance. According to Henkel, BERGQUIST LIQUI FORM TLF 10000 provides 10.0 W/m-K thermal conductivity and is ideal for applications where environments can be extreme or unpredictable and reliability is critical.

“The push toward digital, data-driven control across market sectors has given rise to high power density component designs that can deliver exceptional processing speeds,” said James Edmondson, Ph.D., IDTechEx senior technology analyst. “This includes many applications—from 5G baseband units to small cells and Wi-Fi 6E devices in urban areas to EV mobility to AI and robotic technologies—and they all require reliable thermal management solutions that are rugged enough to withstand dynamic environments, positioning uncertainty and high wattages. Our market research confirms the need for dispensable, high thermal conductivity TIMs that can meet today’s performance and volume processing demands and thermal gels have proven to be an effective solution.”

According to Henkel, the silicone gel BERGQUIST LIQUI FORM TLF 10000 material provides additional advantages, including:

- Reliability—high gap stability for gaps ranging from 0.5-1.5 mm; excellent thermal cycling capability

- Thermal transfer—low thermal impedance of 0.45 Kcm2/W at 0.5 mm bond line thickness; high thermal conductivity of 10.0 W/m-K

- Excellent cycle time and waste reduction—fast and easy dispensing and compatibility with a wide range of dispensing equipment options; stable viscosity for less material waste

- Low stress—lower dispensing pressure and assembly force place less stress on components

“Fast data transfer and immediate information access are necessities for modern-day life,” said Wayne Eng, global head of market strategy for Henkel Data & Telecom. “Components and systems are becoming more powerful to meet the high bandwidth and data processing demand and their dependable performance relies on optimized function. Henkel has developed a unique TIM gel solution that nearly doubles the thermal performance of its predecessor while balancing exceptional heat-dissipating capability with flexible production characteristics. We have taken a leading role in the TIM gel space and continue to innovate beyond present-day requirements to deliver next-generation performance.”

Additional details are available at www.henkel-adhesives.com/us.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!