Home » Keywords: » light-cure adhesives

Items Tagged with 'light-cure adhesives'

ARTICLES

Automotive adhesive delivers high precision for active alignment of camera modules, reducing cost, time, and CO₂ emissions.

Read More

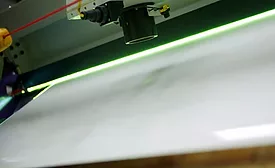

How Formulation and Coating Method Impact UV HMPSAs

Understanding how tackification and coating method impact the effectiveness of UV curing helps to ensure that UV HMPSA properties are properly balanced for their intended end-use application.

February 15, 2024

Arkema Discusses Integrated PSA Offering

Tim Pione outlines Arkema’s position in pressure-sensitive adhesives and what the company has planned for the future.

July 11, 2023

How to Build a Better Flashing Tape

UV-cured acrylic adhesives are enabling the next generation of high-performance flashing tapes.

June 13, 2022

Product Profile

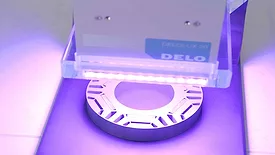

UV-Activated Silicone Adhesives for Autonomous Automotive Sensors

Newly developed UV-activated, dual-cure silicones can protect sensors in autonomous vehicles from the heat, cold, moisture, and stress that result from the rigors of the automotive environment.

May 11, 2022

Core-Shell Masterbatches in Acrylate Monomer

New liquid tougheners offer multiple benefits for structural adhesives and thermoset systems.

February 21, 2022

BOSTIK: Engineering Adhesives for Electronics Manufacturing

The new versatile and single-component hot-melt polyurethane reactive range has been designed specifically for the manufacture of miniaturized handheld and wearable electronic devices.

January 13, 2022

Keep the info flowing with our newsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing