Editor's Memo

Assembly (Adhesives) Required

Most of the "things" we use every day are not born, they are made, and assembly is definitely required.

Practically every product we buy needs to be assembled in order to be operational. Very few of the “things” that make our lives possible and/or enjoyable are simply born. I’m not talking about our families and friends, or even the household pets. (“Assembly” of living things is beyond the scope of this discussion.)

Sure, an argument could be made for the produce aisle. But even if we take genetically modified food out of the equation, those potatoes didn’t magically appear on the supermarket shelf or even at the farmer’s market. They had to be planted, cultivated, picked, and transported. All of those steps require equipment—and most of those “things” had to be assembled, one way or another.

So I’m talking about the “stuff” that we use. Big stuff like cars, trucks, airplanes, and MRI machines. Little stuff like phones, fitness trackers, and speakers. These things are not born, they are made, and assembly is definitely required.

As products change and technologies become more complex, the assembly process must evolve as well. The tools, processes, and parts used to produce Henry Ford’s Model T are worlds apart from those in the plants that produce today’s cars, even those that are powered by traditional internal combustion engines. When we start looking at electric and hybrid vehicles, the difference is truly astonishing; Mr. Ford would be positively gob smacked.

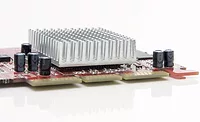

Electric vehicles are exceptionally complex pieces of equipment, and their assembly comes with some specific challenges. One element that can be particularly tricky is the high-voltage battery. Heat dissipation is a major issue, and—as with everything else in the transportation industry—weight is an important consideration. The cooler and lighter these batteries can be, the better.

Adhesives and sealants can be used to address both of those concerns. Turn to “Adhesive Technologies Help Electric Vehicles Go the Distance” to learn about the myriad products that can help facilitate the effective assembly of high-voltage batteries for electric vehicles.

Of course, some of these adhesives and other materials can bring challenges of their own, such as high viscosity or abrasive fillers that cause issues with dispensing. “High-Speed Dispensing for High-Voltage Batteries” details new technologies that can reduce bottlenecks and increase efficiencies.

Where do you think the future of assembly adhesives is headed? I’d love to hear what you think! Please contact me at (248) 786-1704 or suttons@bnpmedia.com to share your ideas.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!