Home » structural adhesives

Articles Tagged with ''structural adhesives''

Lubribond Benelux offers a range of adhesives and chemical bonding agents including industrial adhesives and silicones.

Read More

DuPont Takes Steps to Increase Capacity for Automotive Adhesives in Europe

The investment will expand capacity to support growth in vehicle electrification.

May 24, 2021

Top 5 News that Sticks

Sika’s Latest Acquisition is Top News

Last week, readers were most interested in Sika’s announcement regarding its planned acquisition of Hamatite.

May 17, 2021

DuPont Structural Adhesives Named Silver Winner of 2021 Edison Award

The Edison Awards recognize innovative new products, services, and business leaders.

May 4, 2021

DuPont to Build New Adhesives Manufacturing Facility in China

Products manufactured at the facility will serve customers in the transportation industry, primarily vehicle electrification applications and lightweighting.

April 26, 2021

From the Editor

Exploring Assembly Applications for Adhesives and Sealants

From automotive and construction to general industrial applications, the use of adhesives and sealants is expanding in assembly operations around the world.

April 23, 2021

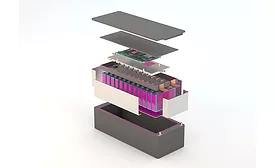

DELO: Thermally Conductive Battery Adhesive for Hybrid Vehicles

The adhesive allows battery cells to be bonded into a battery's housing while dissipating the heat generated during operation.

April 13, 2021

Top 5 News that Sticks

Sustainability Announcements from tesa Garner Strong Reader Interest

Last week, readers were most drawn to news from tesa regarding a new sustainability report and the appointment of a chief sustainability officer.

April 5, 2021

Advancing Adhesives

Structural Adhesive Pushes Performance Boundaries for Composite Armor Systems

A new high-strength and highly ductile adhesive offers performance benefits in the harshest operating environments.

April 5, 2021

Scott Bader Expands Production Capacity for Structural Adhesives in France

The company reports that the approximately $2.1 million investment is in response to increasing customer demand for its products.

March 25, 2021

Keep the info flowing with our newsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing