Home » Keywords: » gap fillers

Items Tagged with 'gap fillers'

ARTICLES

Dow Wins Six 2021 Edison Awards

The company received five gold awards and one silver award.

May 12, 2021

Ask Dr. Dave

Could you please suggest an epoxy resin, along with a hardener and accelerator, to use as a raw material in the production of a high-temperature-resistant adhesive?

Dr. Dave provides details regarding the use of inorganic vs. organic adhesives for high-temperature applications.

May 29, 2020

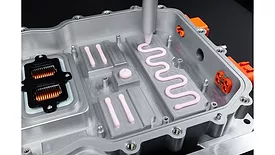

Electric Vehicles and the Growing Significance of Adhesives and Sealants for Battery Assembly

Adhesives, sealants, and heat transfer materials used in battery assembly operations will find myriad opportunities in the exciting electric vehicle market.

March 9, 2020

PANACOL: Fast-Curing Epoxy Adhesive for Cosmetic Packaging

According to Panacol, the adhesive can be applied and cured quickly due to its accommodating dispensing properties.

January 30, 2020

Shin-Etsu Silicones to Showcase Thermal Management Sensor Application Products at Automotive LiDAR Conference

SESA’s focus for LiDAR and automotive sensors will reportedly be its silicone thermal interface materials (TIMs); visible light-blocking encapsulants; UV-curable, low-modulus adhesives; and anti-smudge coatings.

September 20, 2019

Keep the info flowing with our newsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing