Testing/Quality Control

Strategic Solutions

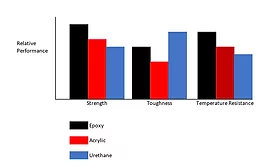

Three key steps must be undertaken when considering the use of adhesives in assembly operations.

Read More

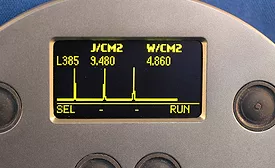

Understanding and Measuring UV LEDs

It is important to consider the variables associated with the LED source and proper measurement tools in order to understand, maintain, and control the adhesive curing process.

October 6, 2021

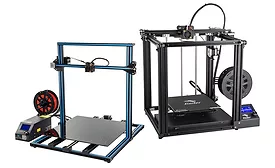

EPIC RESINS: Additive Manufacturing Capabilities

The versatile 3D printing units can be used in numerous applications.

September 30, 2021

Excelitas Completes PCO Acquisition

The acquisition expands Excelitas’ technological scope and its geographic footprint in Europe, North America, and Asia.

September 14, 2021

ALTANA Sees Double-Digit Growth in All Divisions in 2021 First Half

All four divisions recorded double-digit growth rates in the first half of 2020.

August 23, 2021

H.B. FULLER: Spine Adhesive Consulting Service for Softcover Books and Magazines

The FullVision digital platform for bindery quality control is designed to improve efficiency, optimize production, and control costs.

August 17, 2021

Enhanced Durability and Life Expectancy of Silane-Modified Polymer-Based Formulations

Silane-modified polymers (SMPs) are particularly suitable for formulating elastic adhesives, sealants, and coatings. How can additives help optimize performance?

August 6, 2021

Top 5 News that Sticks

Avery Dennison Expansion Leads the News

Last week, news from Avery Dennison regarding its planned expansion in Ohio drew the most reader interest.

July 12, 2021

Selecting and Testing Skin Adhesives for Medical Fixation Devices

The development of adhesives and substrates for wearable medical devices is challenging and requires careful consideration due to the nature of human skin and the characteristics of the specific device.

July 7, 2021

Excelitas Announces Agreement to Acquire PCO

PCO is the latest in a series of strategic acquisitions by Excelitas Technologies.

July 1, 2021

Keep the info flowing with our newsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing