Strategic Solutions

When creating a strategy for digital tools, companies should review their corporate goals and resources, focus on customer interactions, and balance the risk and reward.

Read More

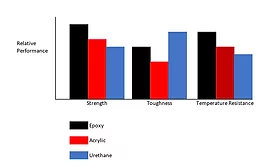

Adhesives for Lightweighting of Structures—Drivers, Selection, Challenges

Lightweighting of structures and combining of materials to take advantage of their best properties is becoming a part of engineering design, and adhesives will play an increasing role in those future designs and applications.

October 27, 2022

Strategic Solutions

Opportunities and Challenges of Biomimicry in Adhesives R&D

Though bioinspired approaches to adhesive R&D often lead to great improvements in the lab, translating these sophisticated chemistries to commercial scale is a considerable challenge.

June 8, 2022

Strategic Solutions

The Wonderful Wide World of (Pressure-Sensitive Adhesive) Tape

The pressure-sensitive tape market continues to expand, with global growth rates predicted to be over 6% through 2030.

April 26, 2022

Strategic Solutions

PSA Wound Dressing Adhesion and Skin Type: A Delicate Balance

Consideration must be given to various skin types to ensure dressings can be securely attached and easily removed without skin damage.

December 15, 2021

Strategic Solutions

Sustainable Adhesives in Construction and Packaging

Though sustainability can be difficult to define, many types of adhesives contribute to more sustainable construction and packaging products.

November 8, 2021

Strategic Solutions

Assembly with Adhesives

Three key steps must be undertaken when considering the use of adhesives in assembly operations.

October 11, 2021

Strategic Solutions

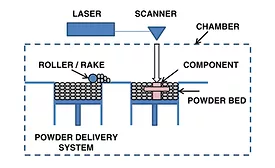

Weighing the Cost Benefit of Complex Design in 3D-Printed OEM Parts

Adhesive bonding opportunities are exponentially increasing with the design complexities of polymer and metal additive manufacturing.

September 10, 2021

Strategic Solutions

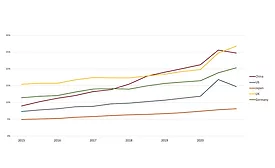

COVID-19 Impact on Global Shipping and Packaging Dynamics

The continued transition away from brick-and-mortar to ecommerce brings demand for packaging innovations that enable faster delivery and better content protection from shock or temperature variations.

May 19, 2021

Strategic Solutions

Patenting Considerations for Composition Inventions in the Adhesives and Sealants Industry

Incorporating compositions into process or assembly/device claims, although restrictive, can afford some protection. But is it enough?

April 15, 2021

Keep the info flowing with our newsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing